Table of Contents

Hero Shot

Step Response

The step response of a system is the output behavior of a system when subjected to a step input. A step input is a type of input signal that changes from one value to another, typically from zero to a constant value, instantaneously at a specified time.

https://en.wikipedia.org/wiki/Step_response

https://en.wikipedia.org/wiki/Step_response

Capacitor

Working Principle

Capacitive Sensing

Working

Types of Capacitive Sensors

Capacitive Multitouch

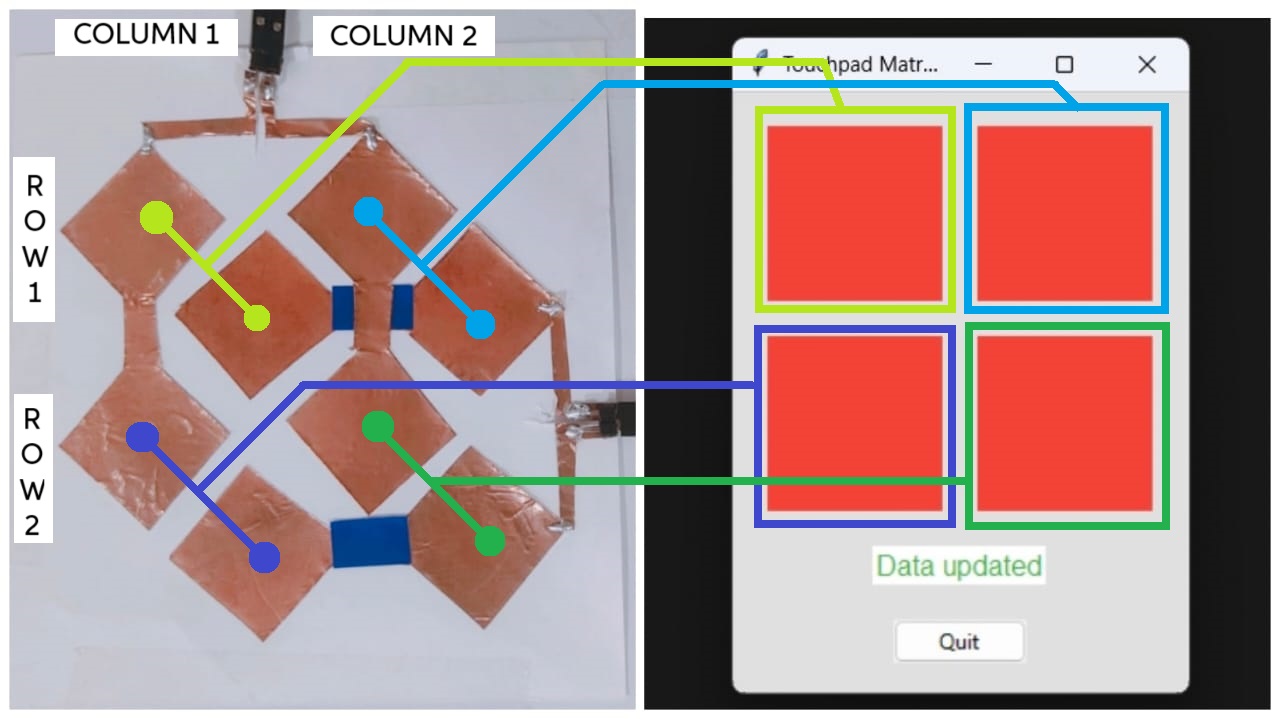

Creating a capacitive multitouch sensor involves designing a grid of conductive material to detect multiple touch points simultaneously. This technology is used in modern touchscreens found in smartphones, tablets, and other interactive devices.

Designing a New Board for Capacitive Multitouch

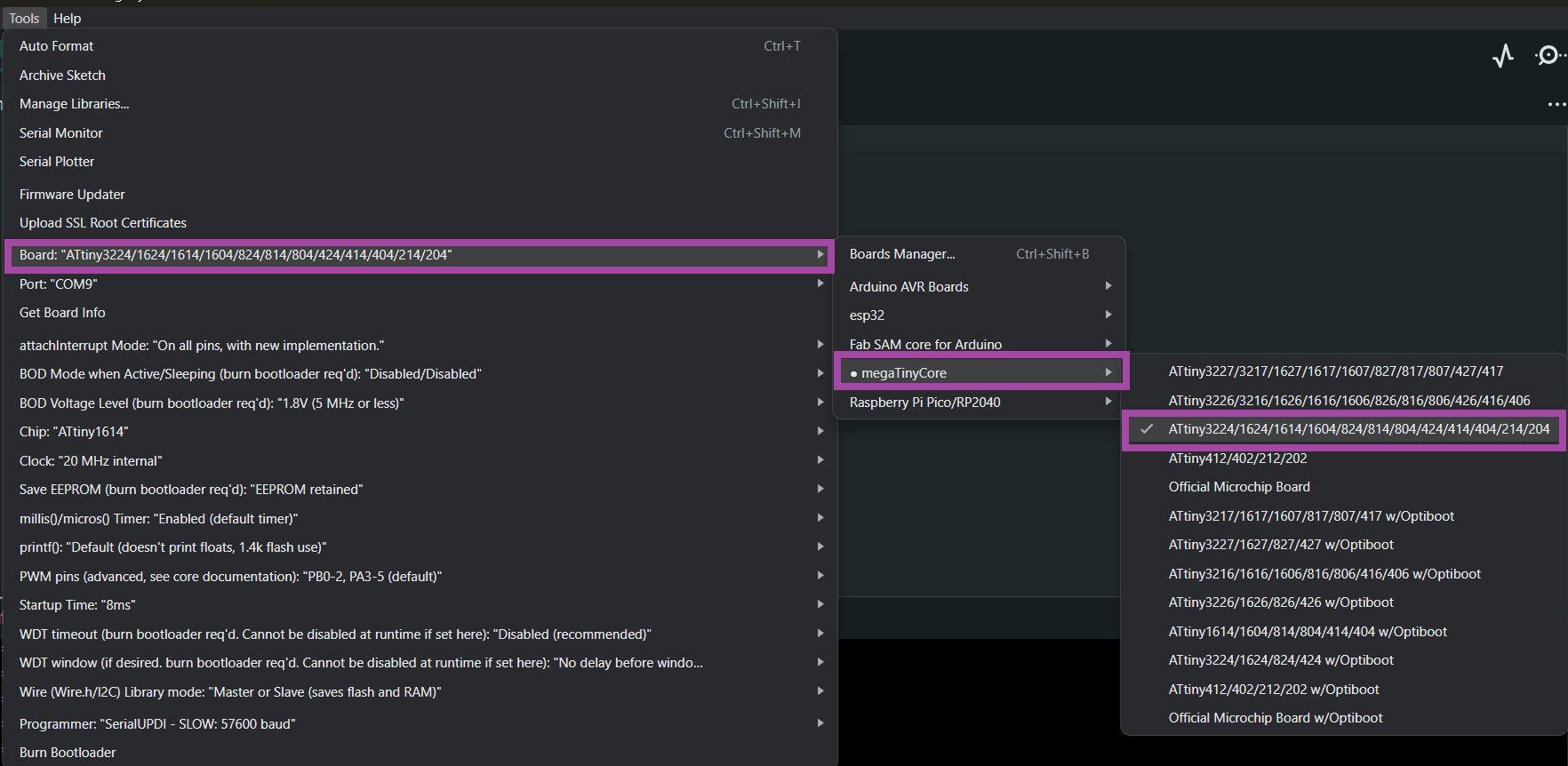

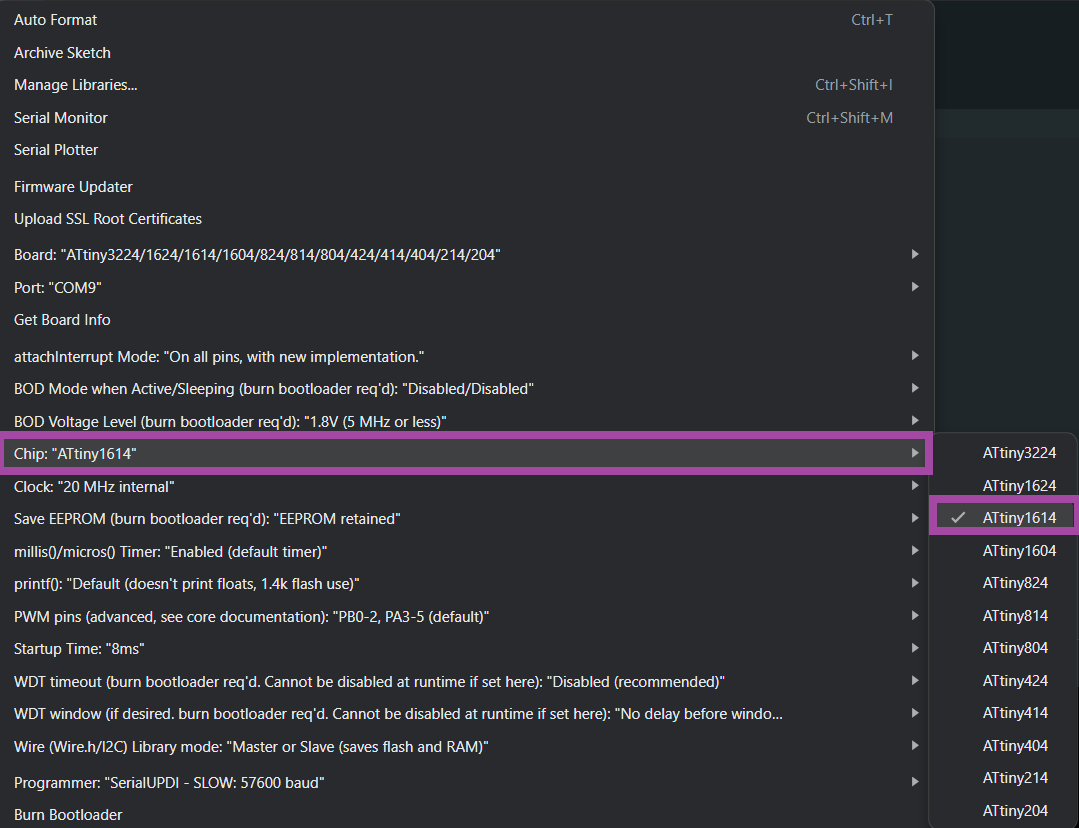

Selecting the Microcontroller

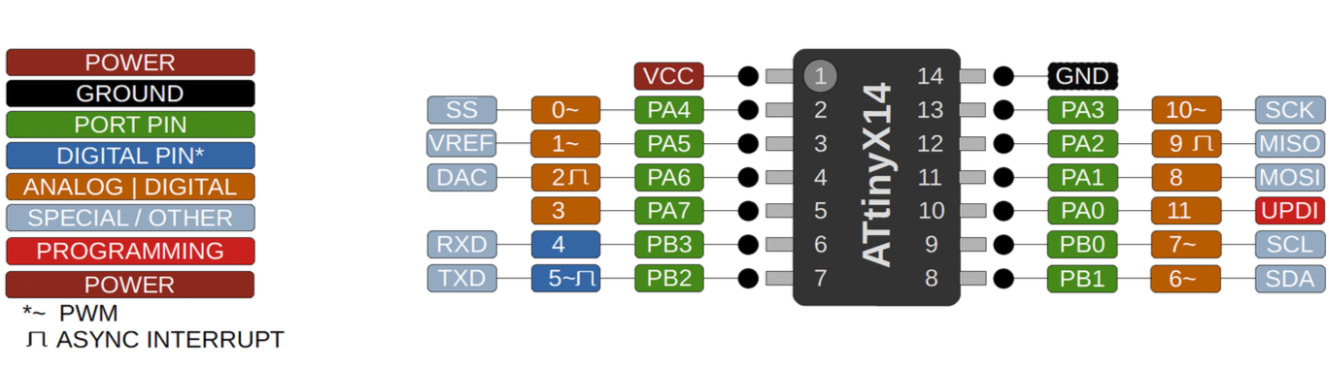

ATtiny1614

The ATtiny1614 is a high-performance, low-power 8-bit AVR RISC-based microcontroller that combines 16KB ISP flash memory, 256B EEPROM, 2KB SRAM, and operates up to 20 MHz. It offers a broad range of features including 18 general purpose I/O lines, 32 general purpose working registers, three flexible timer/counters with compare modes, internal and external interrupts, a serial programmable USART, a byte-oriented 2-wire serial interface, a 10-bit ADC with 10 channels, a programmable watchdog timer with internal oscillator, and five software-selectable power saving modes.

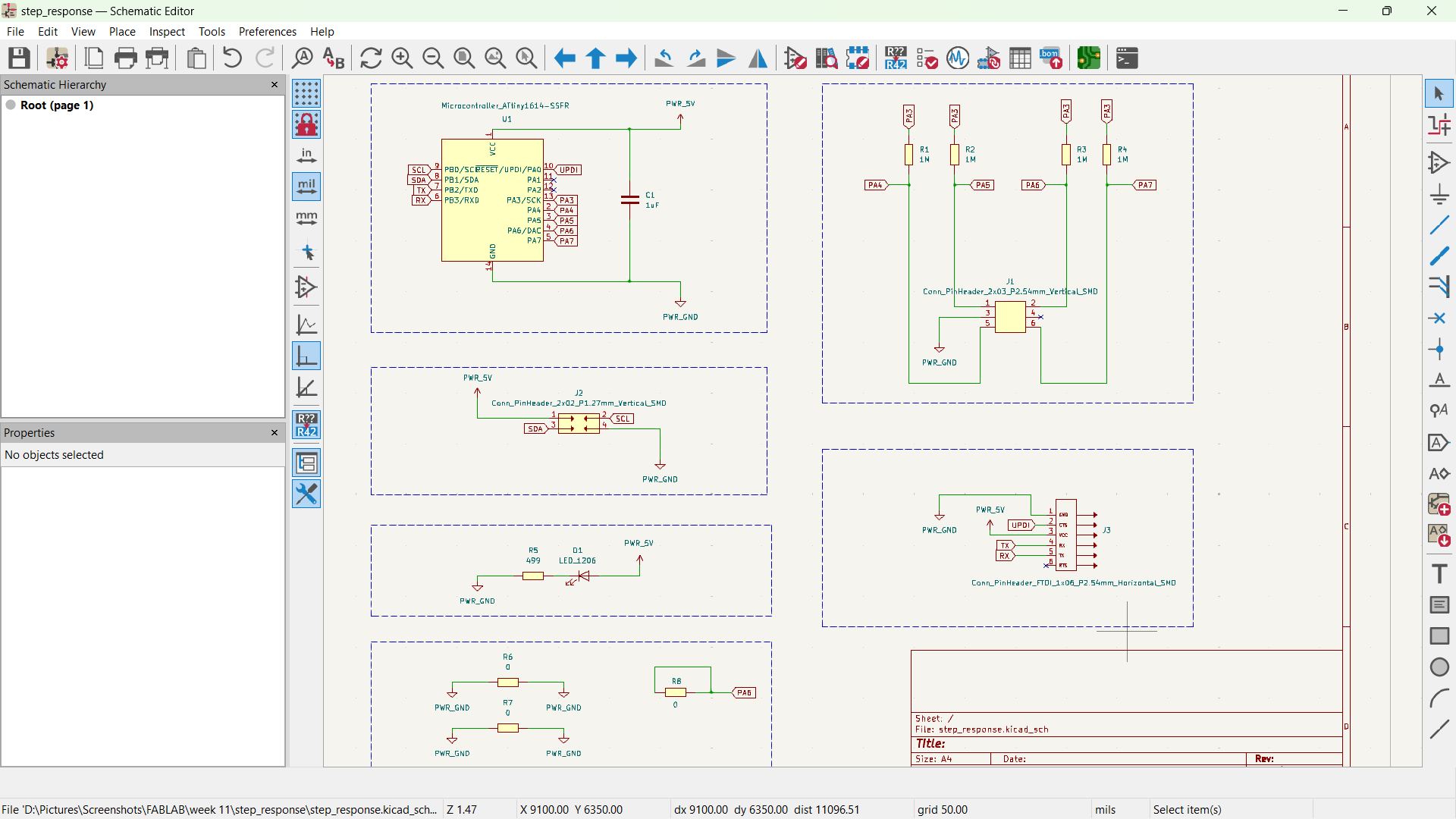

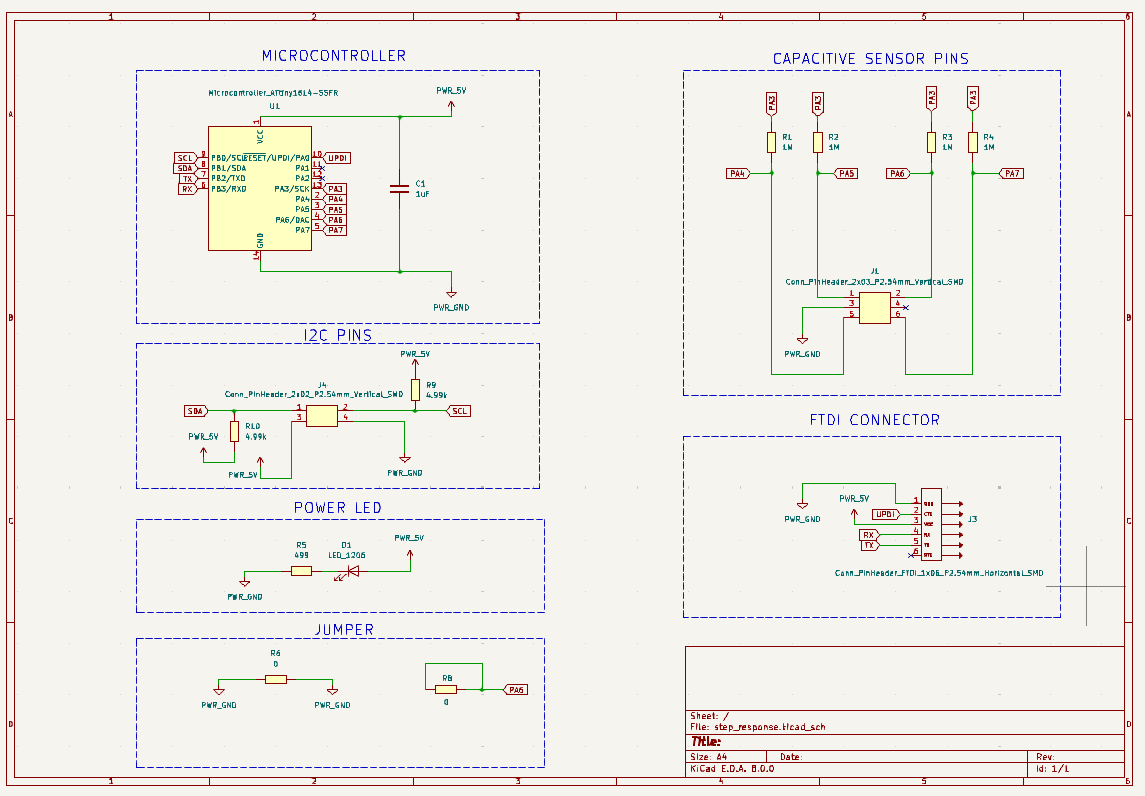

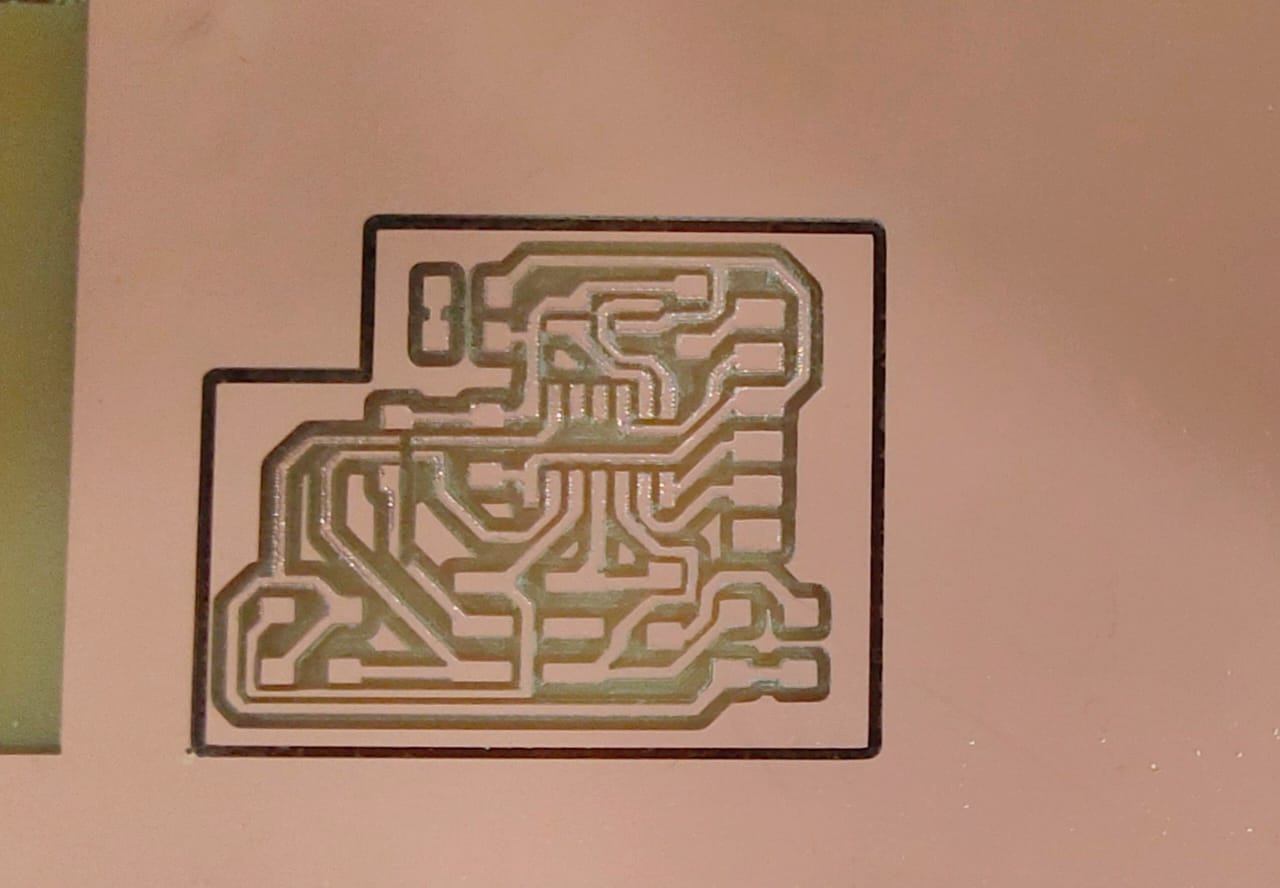

Schematic in KiCad

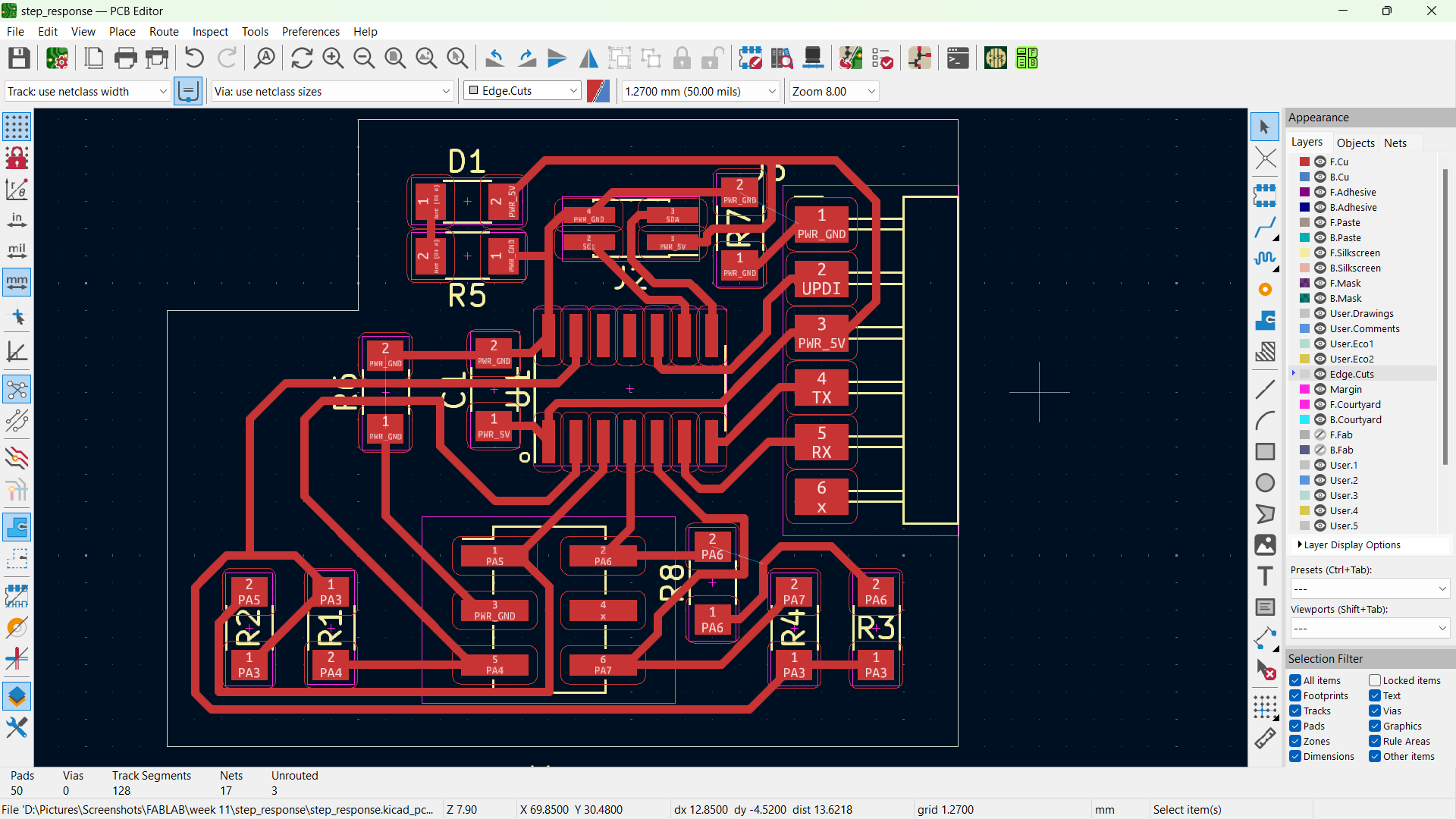

PCB Routing in KiCad

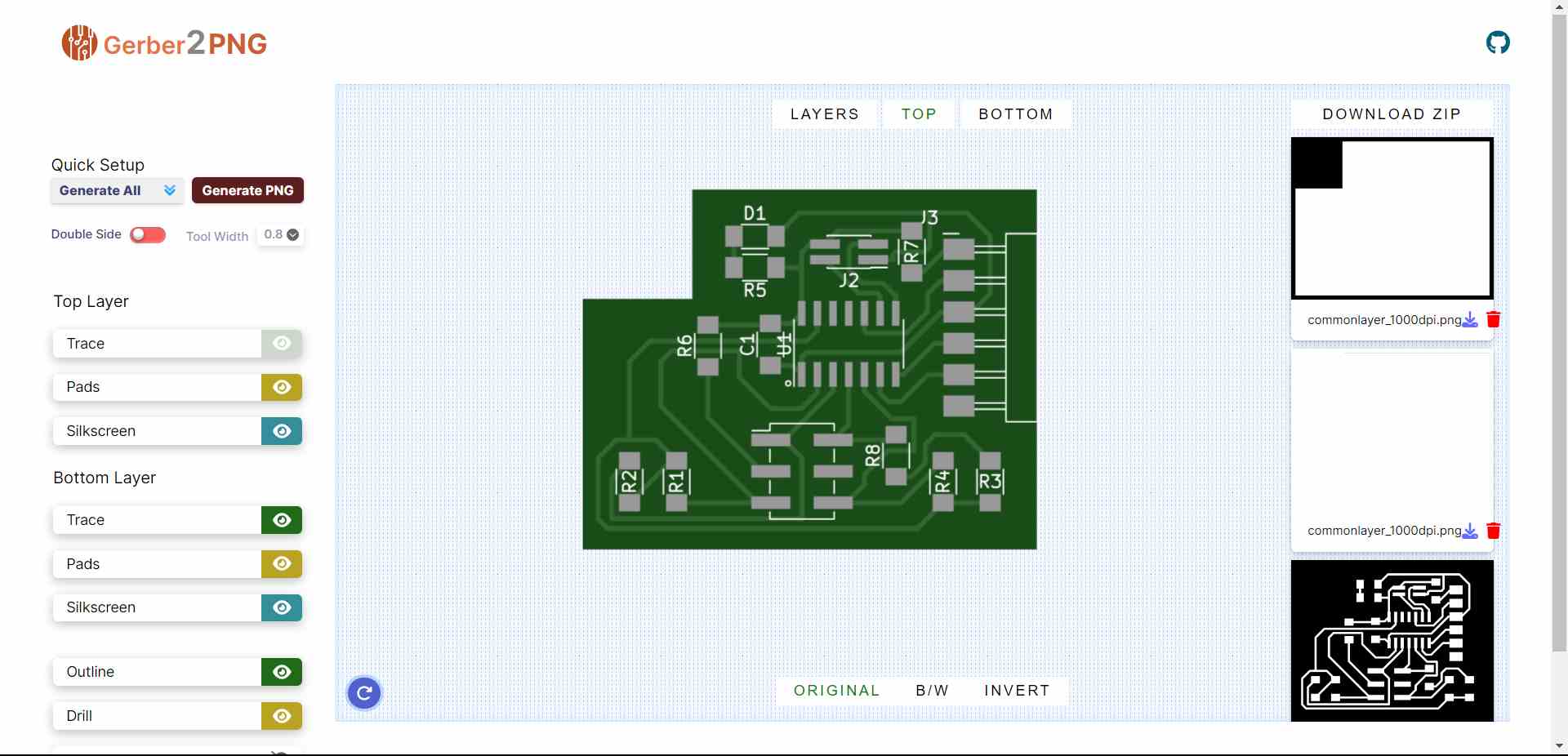

Converting Gerber file to PNG

https://gerber2png.fablabkerala.in/

https://gerber2png.fablabkerala.in/

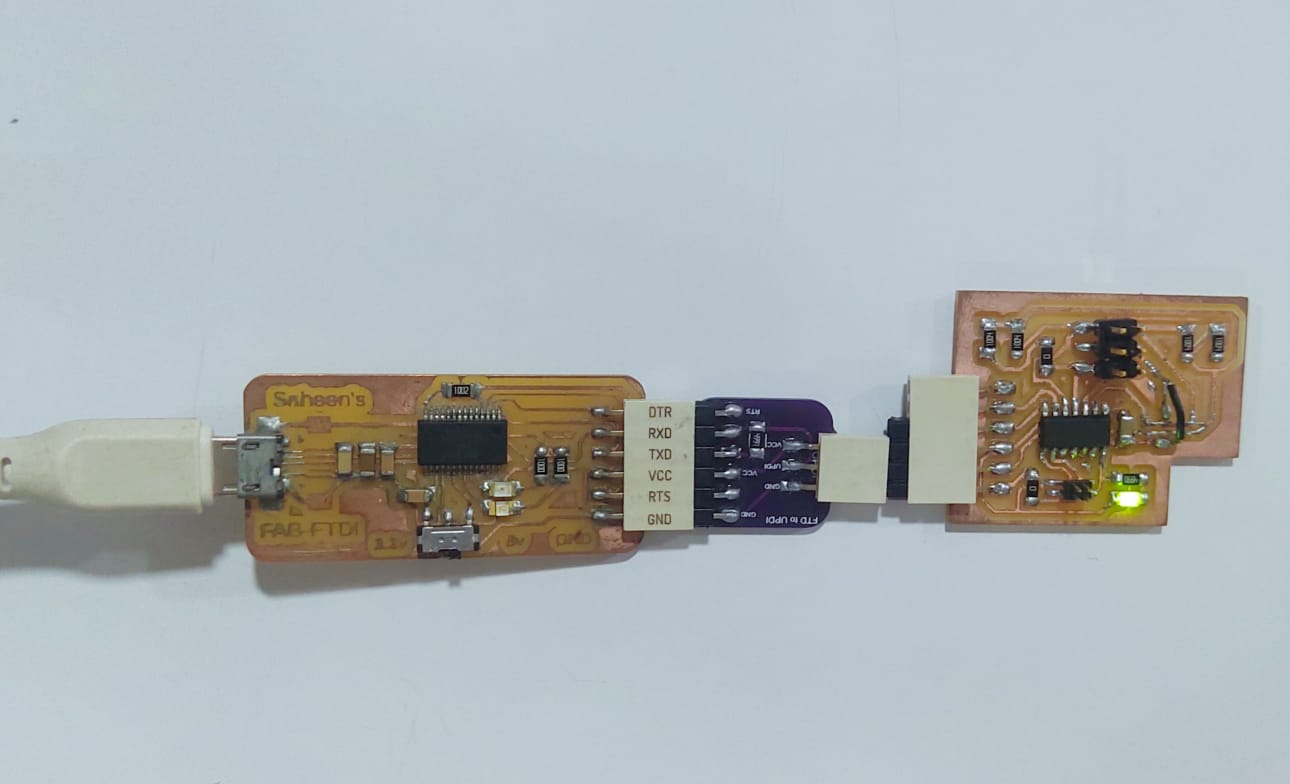

PCB Milling

PCB Soldering

Bill of Materials

| Reference | Value | Qty | Datasheet |

| C1 | 1uF | 1 | https://www.yageo.com/upload/media/product/productsearch/datasheet/mlcc/UPY-GP_NP0_16V-to-50V_18.pdf |

| D1 | LED_1206 | 1 | https://optoelectronics.liteon.com/upload/download/DS-22-98-0002/LTST-C150CKT.pdf |

| J1 | Conn_PinHeader_2x03_P2.54mm_Vertical_SMD | 1 | https://cdn.amphenol-icc.com/media/wysiwyg/files/drawing/95278.pdf |

| J2 | Conn_PinHeader_2x02_P1.27mm_Vertical_SMD | 1 | https://s3.amazonaws.com/catalogspreads-pdf/PAGE94-95%20.050%20MALE%20HDR%20ST%20RA%20SMT.pdf |

| J3 | Conn_PinHeader_FTDI_1x06_P2.54mm_Horizontal_SMD | 1 | ~ |

| R1,R2,R3,R4 | 1M | 4 | ~ |

| R5 | 499 | 1 | ~ |

| R6,R7,R8 | 0 | 3 | ~ |

| U1 | Microcontroller_ATtiny1614-SSFR | 1 | http://ww1.microchip.com/downloads/en/DeviceDoc/ATtiny1614-16-17-DataSheet-DS40002204A.pdf |

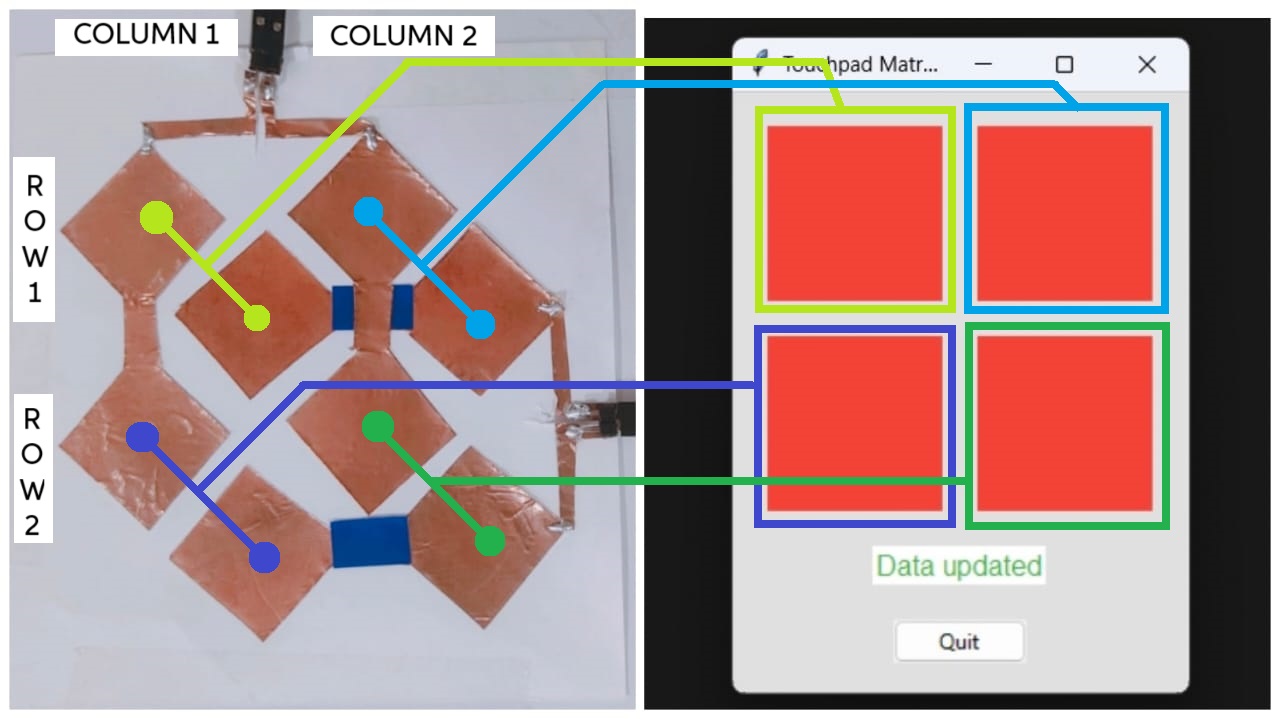

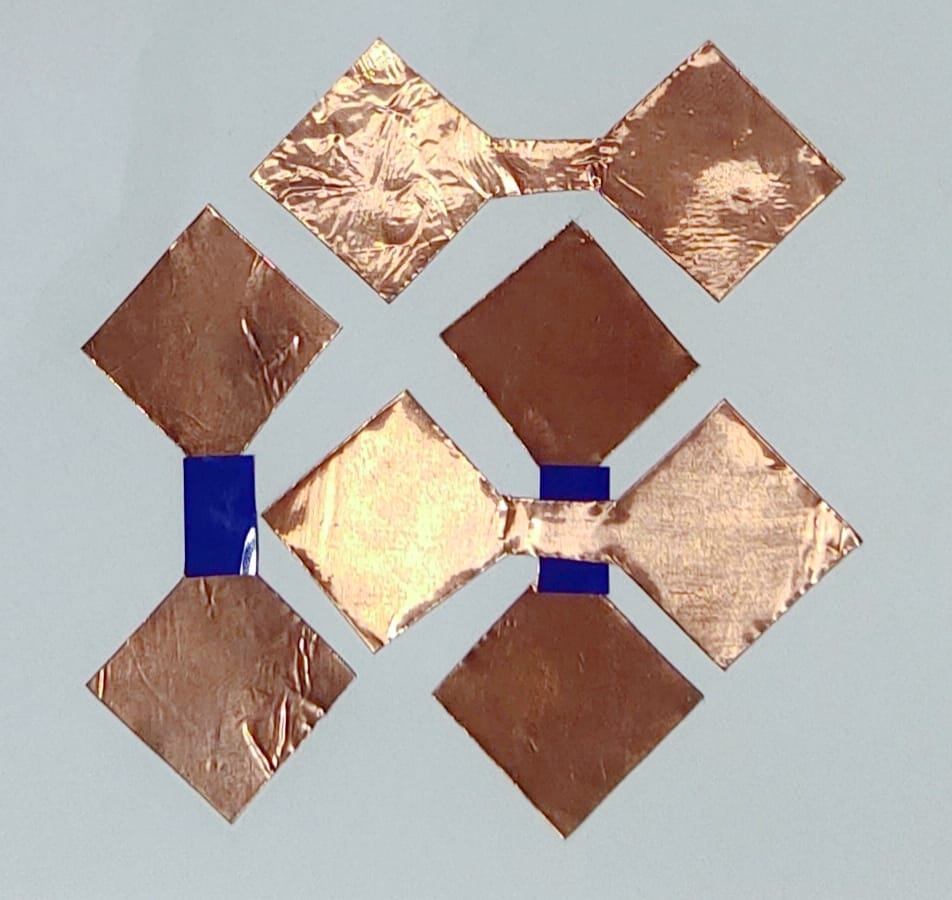

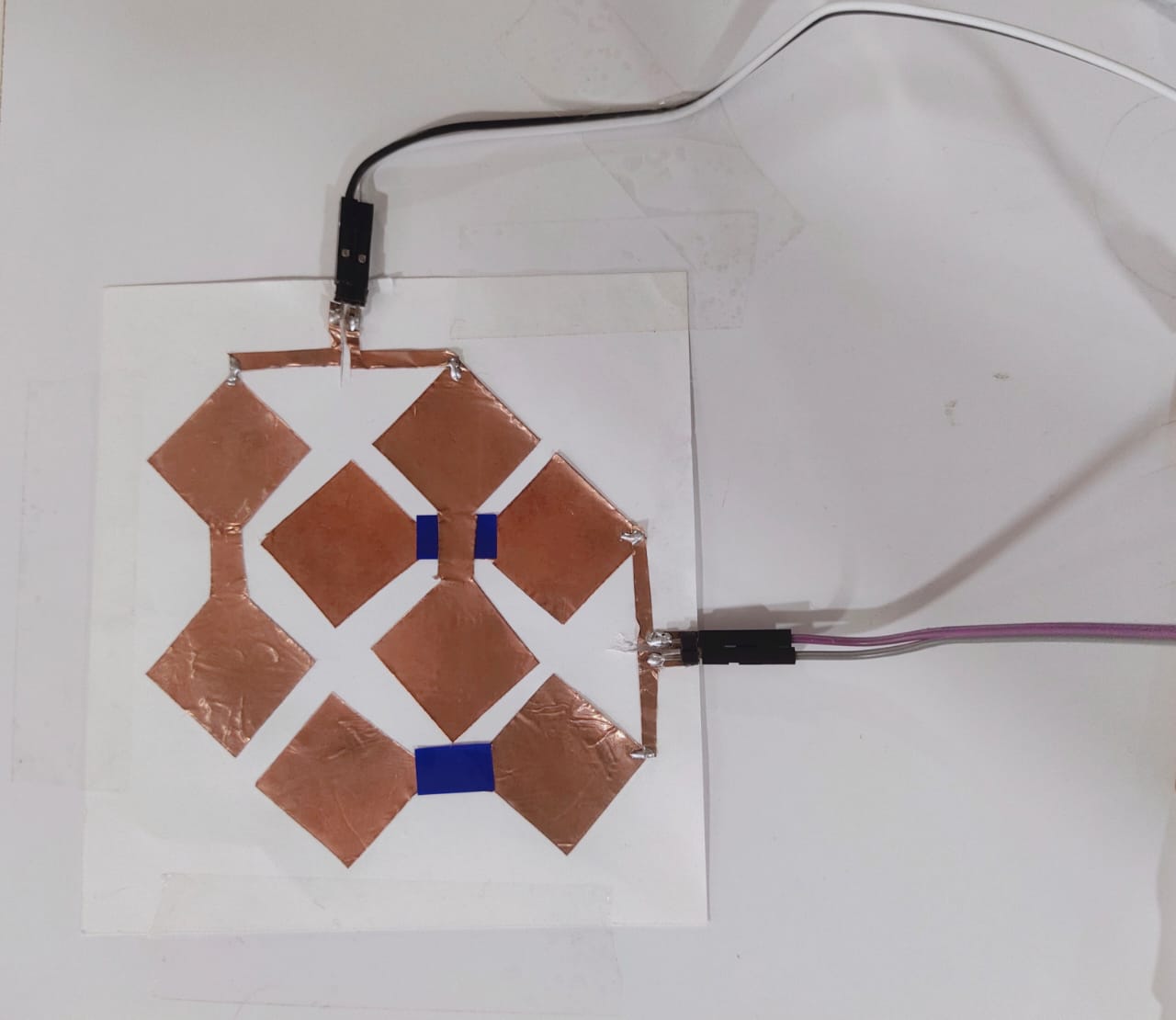

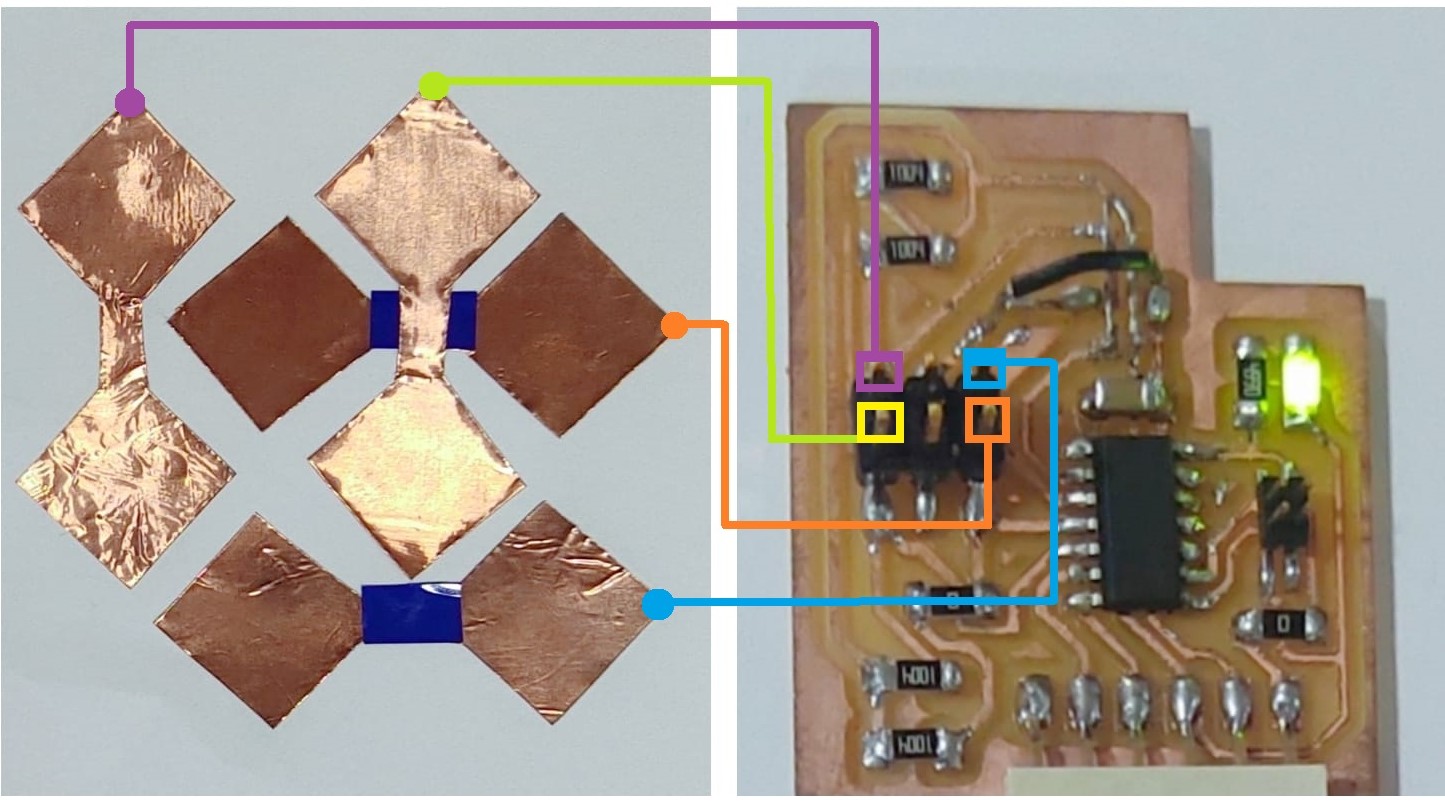

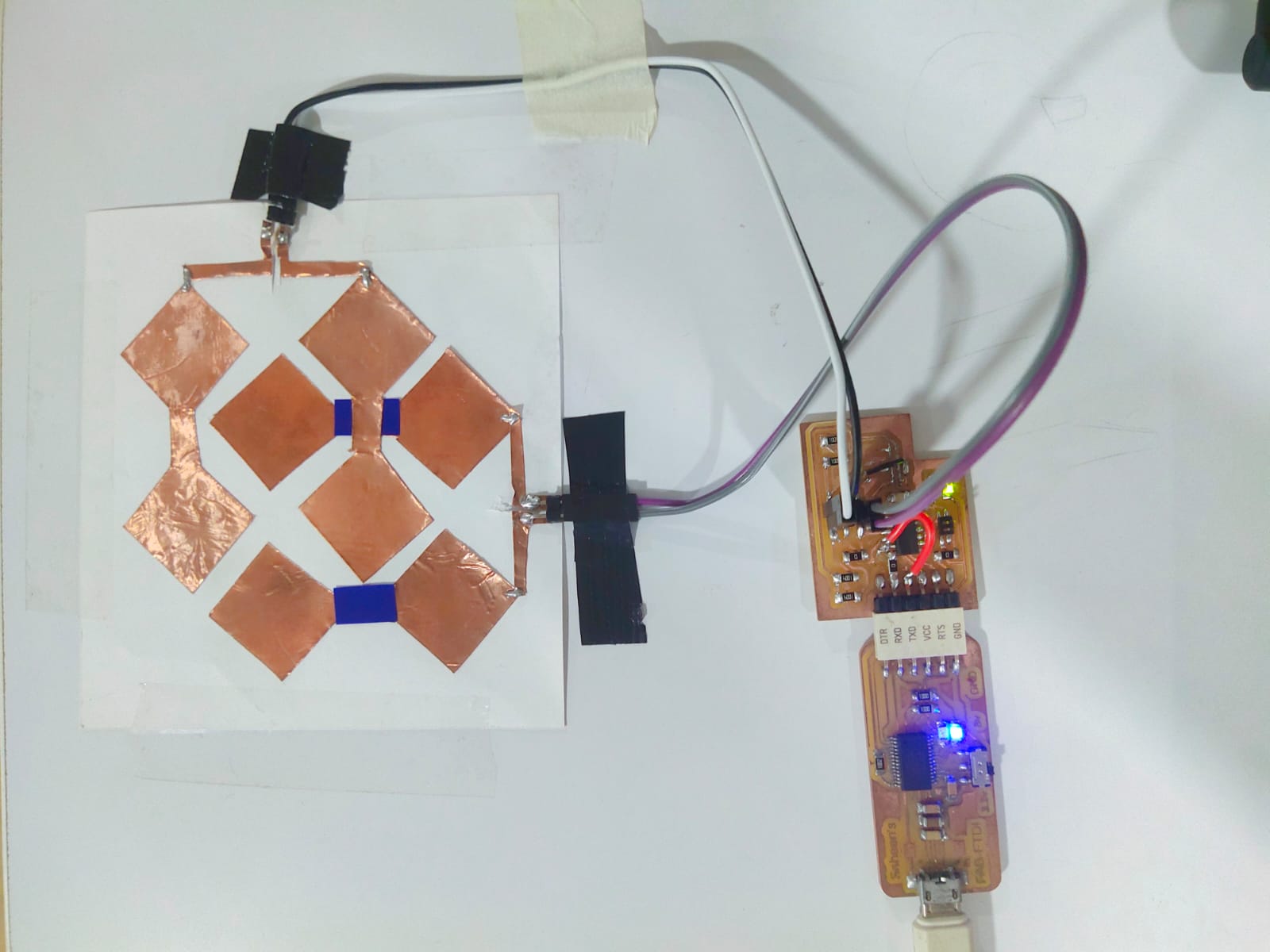

Touchpad Design

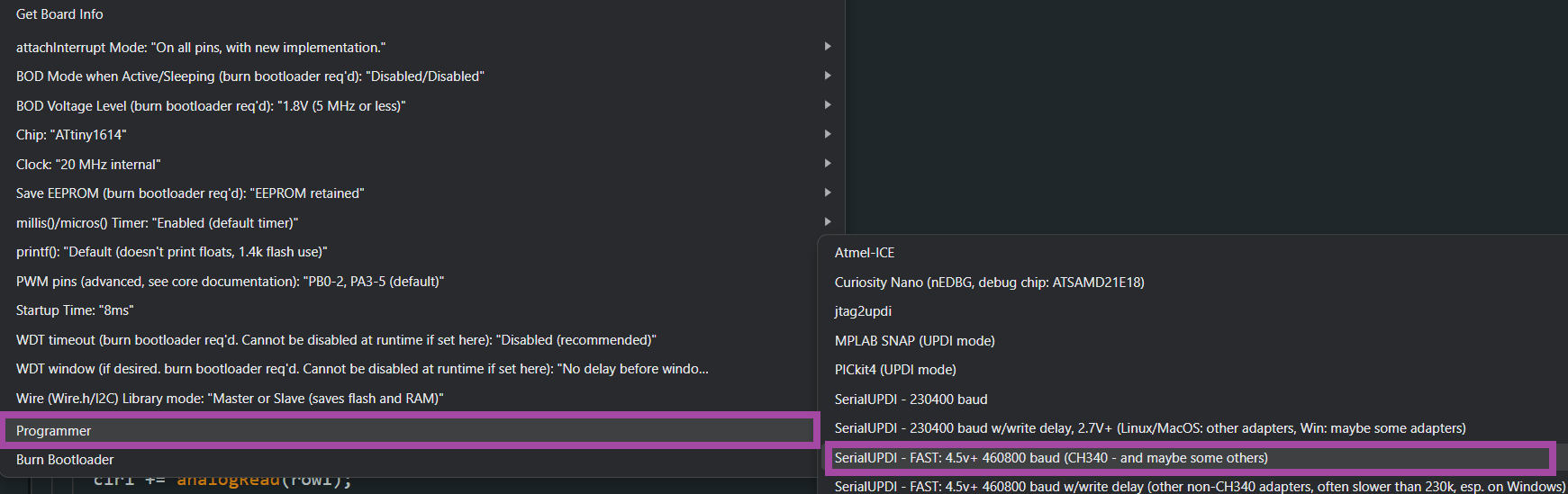

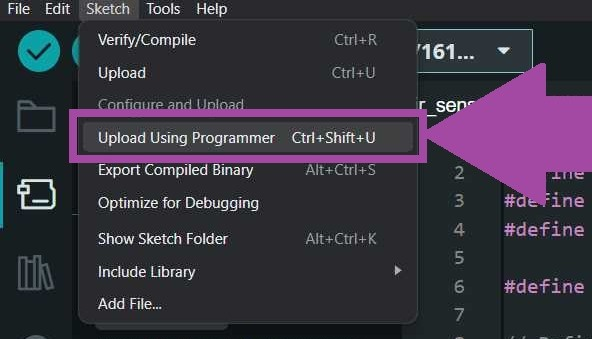

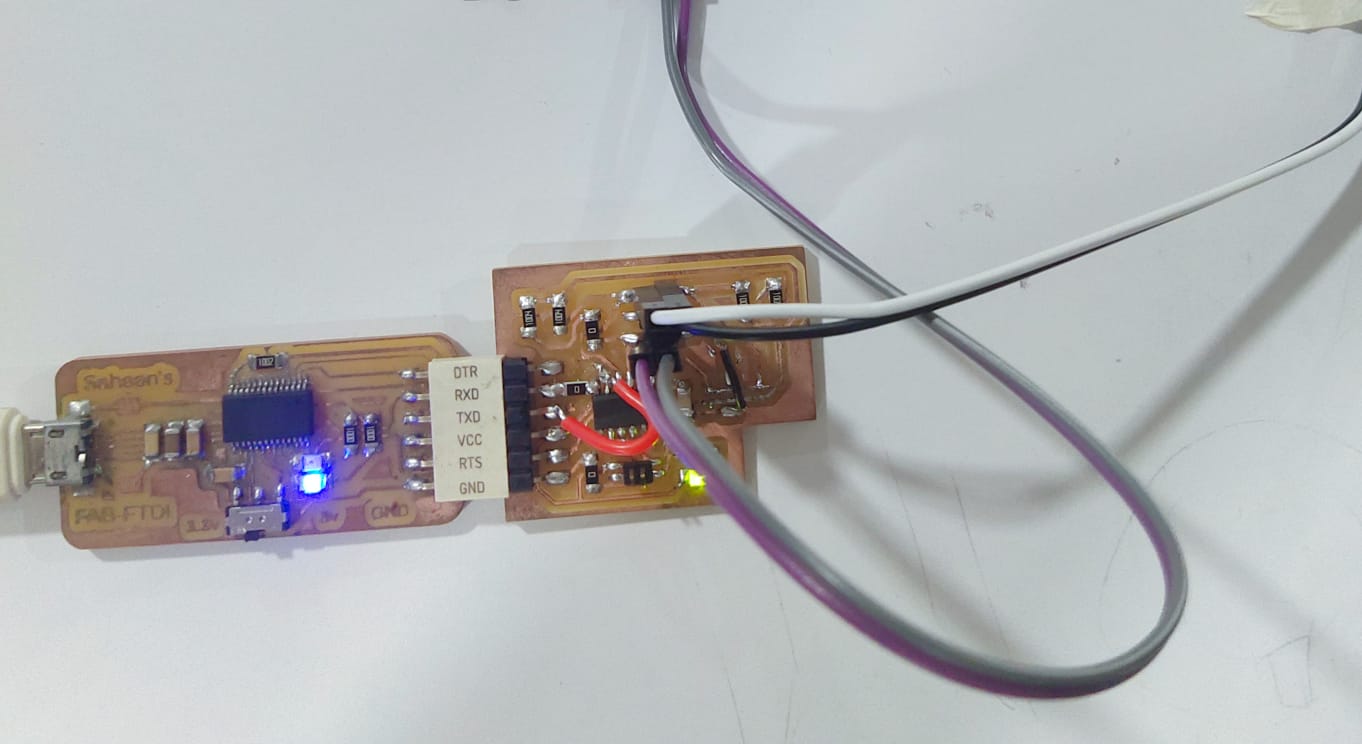

Programming the Board

Access Data Serially

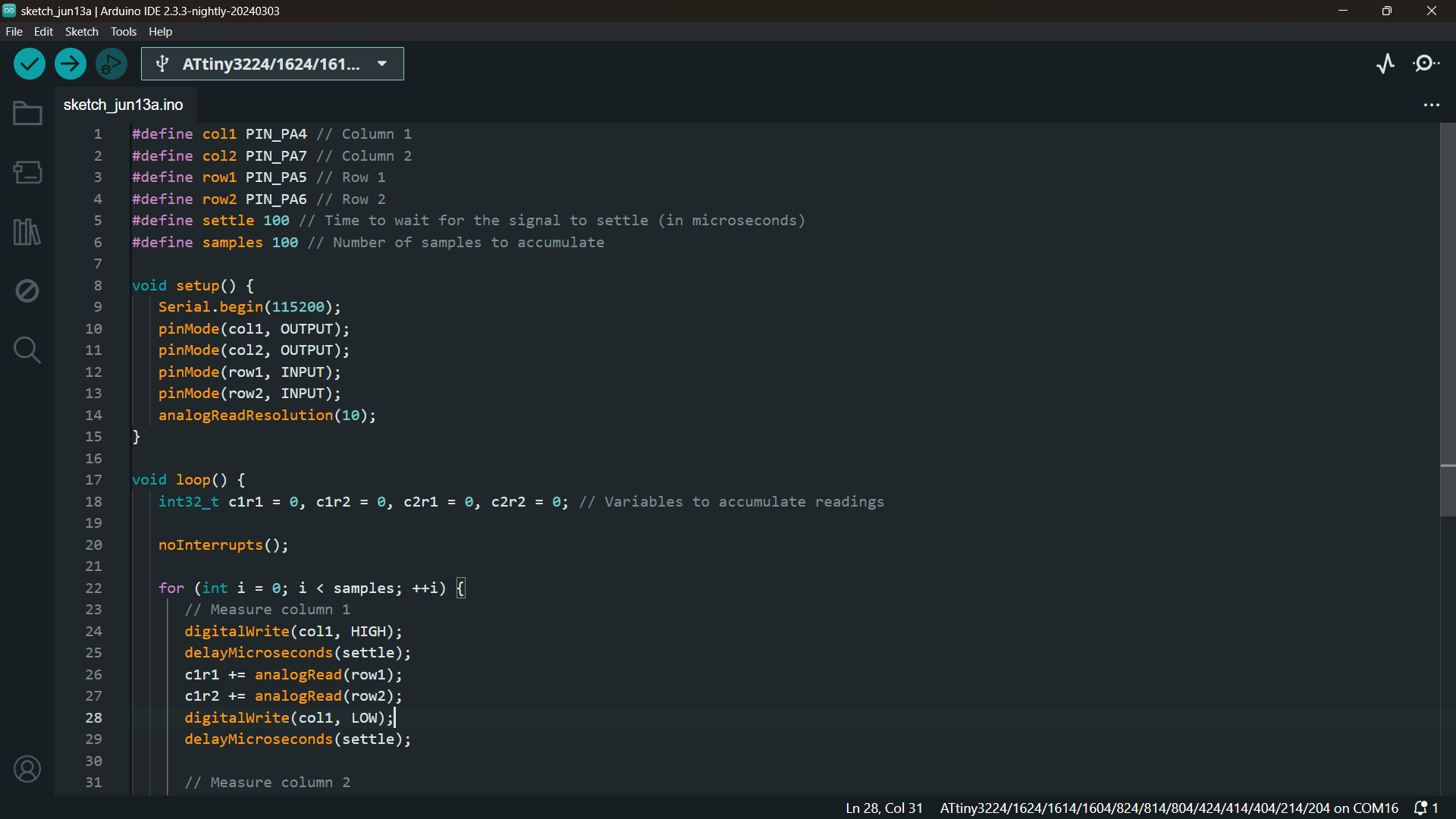

Embedded Program

// Define pin assignments for columns and rows

#define col1 PIN_PA4 // Column 1

#define col2 PIN_PA7 // Column 2

#define row1 PIN_PA5 // Row 1

#define row2 PIN_PA6 // Row 2

// Define constants for signal settling time and number of samples

#define settle 100 // Time to wait for the signal to settle (in microseconds)

#define samples 100 // Number of samples to accumulate

void setup() {

Serial.begin(115200); // Initialize serial communication at 115200 baud rate

pinMode(col1, OUTPUT); // Set column 1 pin as output

pinMode(col2, OUTPUT); // Set column 2 pin as output

pinMode(row1, INPUT); // Set row 1 pin as input

pinMode(row2, INPUT); // Set row 2 pin as input

analogReadResolution(10); // Set analog read resolution to 10 bits

}

void loop() {

// Initialize variables to accumulate readings for each column-row combination

int32_t c1r1 = 0, c1r2 = 0, c2r1 = 0, c2r2 = 0;

noInterrupts(); // Disable interrupts to ensure accurate timing for measurements

for (int i = 0; i < samples; ++i) {

// Measure signals for column 1

digitalWrite(col1, HIGH); // Set column 1 HIGH

delayMicroseconds(settle); // Wait for the signal to settle

c1r1 += analogRead(row1); // Read analog value from row 1 and accumulate

c1r2 += analogRead(row2); // Read analog value from row 2 and accumulate

digitalWrite(col1, LOW); // Set column 1 LOW

delayMicroseconds(settle); // Wait for the signal to settle

// Measure signals for column 2

digitalWrite(col2, HIGH); // Set column 2 HIGH

delayMicroseconds(settle); // Wait for the signal to settle

c2r1 += analogRead(row1); // Read analog value from row 1 and accumulate

c2r2 += analogRead(row2); // Read analog value from row 2 and accumulate

digitalWrite(col2, LOW); // Set column 2 LOW

delayMicroseconds(settle); // Wait for the signal to settle

}

interrupts(); // Re-enable interrupts

// Print the accumulated readings for each column-row combination

Serial.print("C1R1: ");

Serial.print(c1r1);

Serial.print(", C1R2: ");

Serial.print(c1r2);

Serial.print(", C2R1: ");

Serial.print(c2r1);

Serial.print(", C2R2: ");

Serial.println(c2r2);

Serial.flush(); // Ensure all serial data is transmitted before continuing

}⚠️ Calibrate the Sensor

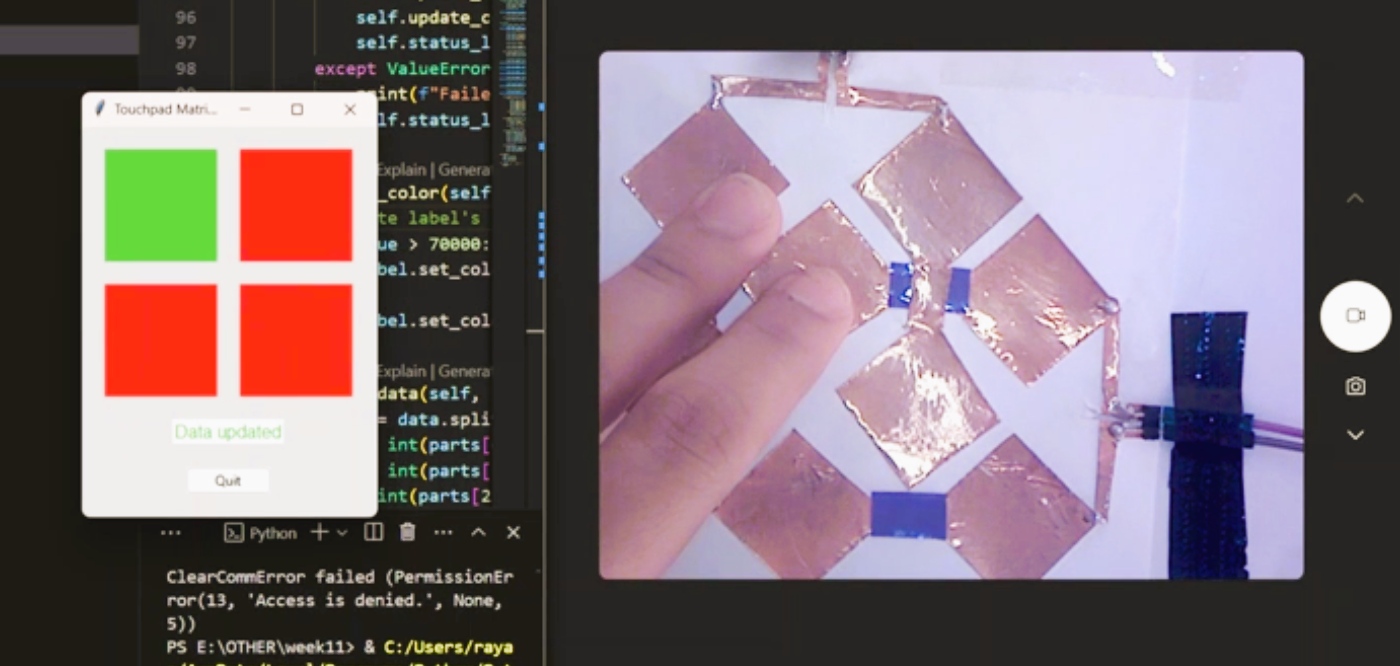

Creating the GUI for the Capacitive Multitouch Pad

Overview of the Implementation

GUI Code

import tkinter as tk

from tkinter import ttk

import serial

import threading

# Define the serial port and baud rate

SERIAL_PORT = 'COM17'

BAUD_RATE = 115200

# Class to handle serial communication

class SerialReader:

def __init__(self, port, baudrate):

# Initialize the serial port

self.serial_port = serial.Serial(port, baudrate, timeout=1)

self.is_running = False

self.thread = None

def start_reading(self, callback):

# Start the thread to read serial data

self.is_running = True

self.thread = threading.Thread(target=self.read_serial, args=(callback,))

self.thread.start()

def stop_reading(self):

# Stop the thread reading serial data

self.is_running = False

if self.thread is not None:

self.thread.join()

def read_serial(self, callback):

# Continuously read from the serial port and call the callback with the data

while self.is_running:

if self.serial_port.in_waiting > 0:

data = self.serial_port.readline().decode().strip()

if data:

callback(data)

def close(self):

# Close the serial port

self.serial_port.close()

# Custom frame to represent a color-changing rectangle

class RectangleLabel(ttk.Frame):

def __init__(self, parent, width=50, height=50, bg="red", **kwargs):

super().__init__(parent, **kwargs)

self.width = width

self.height = height

self.bg = bg

# Create a canvas to draw the rectangle

self.canvas = tk.Canvas(self, width=self.width, height=self.height, bg=self.bg, highlightthickness=0)

self.canvas.pack(fill=tk.BOTH, expand=True)

def set_color(self, color):

# Change the color of the rectangle

self.canvas.config(bg=color)

# Main application class

class App:

def __init__(self, root):

self.root = root

self.root.title("Touchpad Matrix GUI")

self.root.geometry("500x500") # Set square size of the window

# Configure styles for better appearance

self.style = ttk.Style()

self.style.configure('TFrame', background='#e0e0e0') # Set background color for frames

self.style.configure('TLabel', background='#ffffff', foreground='#333333', font=('Arial', 12)) # Set label styles

self.style.map('TButton', background=[('active', '#ffc107')]) # Button color change on click

# Initialize the serial reader

self.serial_reader = SerialReader(SERIAL_PORT, BAUD_RATE)

self.create_widgets()

# Start reading from the serial port

self.serial_reader.start_reading(self.update_display)

def create_widgets(self):

# Create a frame to hold the widgets

self.frame = ttk.Frame(self.root, padding="10")

self.frame.grid(row=0, column=0, sticky=(tk.W, tk.E, tk.N, tk.S))

# Create rectangle labels for the touchpad matrix

self.c1r1_label = RectangleLabel(self.frame, width=100, height=100, bg="red")

self.c1r1_label.grid(row=0, column=0, padx=10, pady=10)

self.c1r2_label = RectangleLabel(self.frame, width=100, height=100, bg="red")

self.c1r2_label.grid(row=1, column=0, padx=10, pady=10)

self.c2r1_label = RectangleLabel(self.frame, width=100, height=100, bg="red")

self.c2r1_label.grid(row=0, column=1, padx=10, pady=10)

self.c2r2_label = RectangleLabel(self.frame, width=100, height=100, bg="red")

self.c2r2_label.grid(row=1, column=1, padx=10, pady=10)

# Add a status label to show updates

self.status_label = ttk.Label(self.frame, text="Waiting for data...", style='TLabel')

self.status_label.grid(row=2, column=0, columnspan=2, pady=10)

# Add a quit button to close the application

self.quit_button = ttk.Button(self.frame, text="Quit", command=self.quit)

self.quit_button.grid(row=3, column=0, columnspan=2, pady=10)

def update_display(self, data):

try:

# Parse the received data

c1r1, c1r2, c2r1, c2r2 = self.parse_data(data)

# Update the color of the rectangles based on the data

self.update_color(self.c1r1_label, c1r1)

self.update_color(self.c1r2_label, c1r2)

self.update_color(self.c2r1_label, c2r1)

self.update_color(self.c2r2_label, c2r2)

self.status_label.config(text="Data updated", foreground="#4caf50") # Bright green color

except ValueError:

print(f"Failed to parse data: {data}")

self.status_label.config(text="Error: Failed to parse data", foreground="#f44336") # Bright red color

def update_color(self, label, value):

# Update the label's background color based on the value

if value > 70000:

label.set_color("#4caf50") # Bright green color

else:

label.set_color("#f44336") # Bright red color

def parse_data(self, data):

# Parse the received data assuming format "C1R2: value, C1R1: value, C2R2: value, C2R1: value"

parts = data.split(',')

c1r2 = int(parts[0].split(':')[1].strip())

c1r1 = int(parts[1].split(':')[1].strip())

c2r2 = int(parts[2].split(':')[1].strip())

c2r1 = int(parts[3].split(':')[1].strip())

return c1r1, c1r2, c2r1, c2r2

def quit(self):

# Stop reading from the serial port and close the application

self.serial_reader.stop_reading()

self.serial_reader.close()

self.root.destroy()

# Main function to start the application

def main():

root = tk.Tk()

app = App(root)

root.mainloop()

# Entry point of the application

if __name__ == "__main__":

main()

Explanation of the Python Code

Final Result

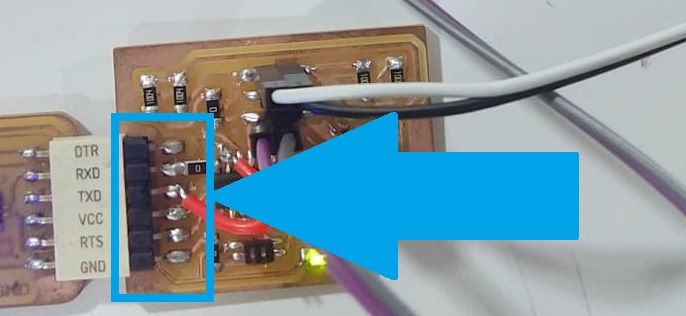

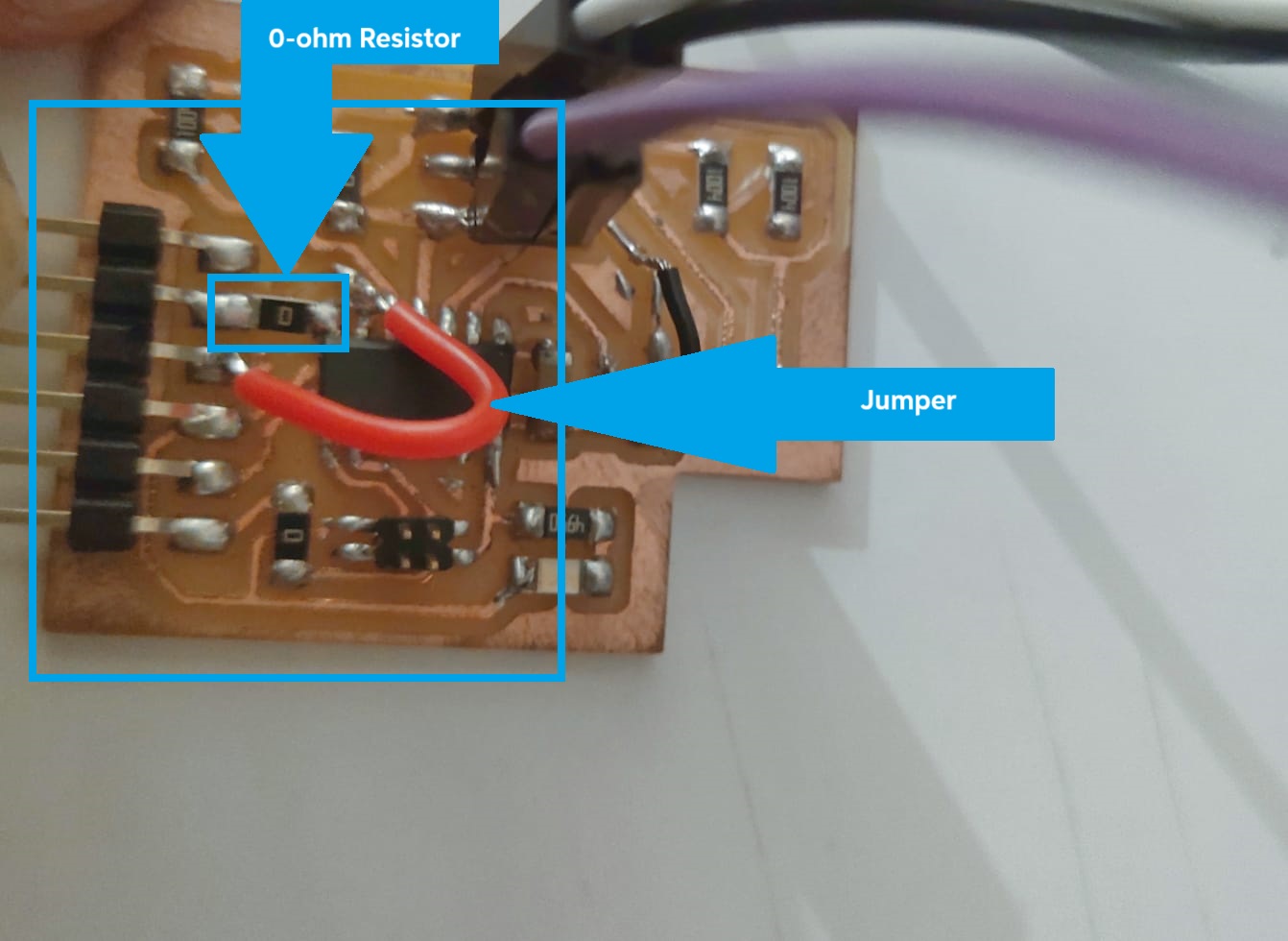

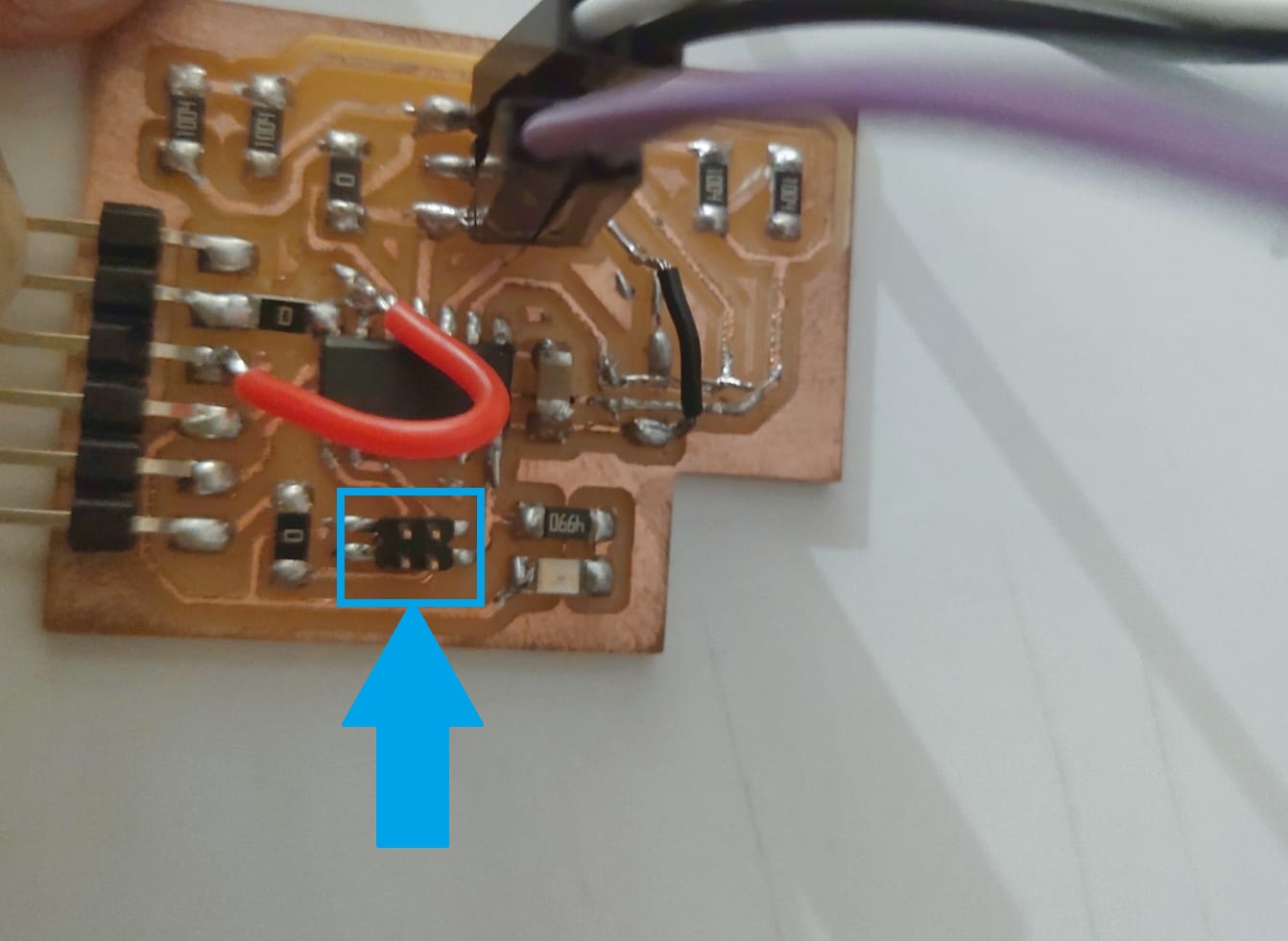

Challenges

Changed the SMT header pins

Reference

https://fabacademy.org/2020/labs/barcelona/students/arman-najari/assignments/week10/

https://fabacademy.org/2020/labs/barcelona/students/arman-najari/assignments/week10/