Hero Shots

Table of Contents

Game Abstract

The Zig Zag Game is a stand-alone wooden skill game designed for a single player. The objective is to roll a ball from one end of a zig-zagging, tiltable platform to the far end, where various scoring zones are marked. The farther the ball travels without falling off the track, the higher the score the player earns.

Game Outcomes

Patience and Precision

Players develop patience as they learn from trial and error and avoid sudden or jerky movements.

Cognitive Development

It acts as a mini cognitive gym, helping children and even adults sharpen focus, planning, balance, and critical thinking.

Fun and Engagement

The game is engaging, making it ideal for leisure activities, or family events. Encourages friendly competition and goal-setting .

Objective

While I was working on the serial robotic manipulator, I got an urgent task for the development and management of the game section for the Kerala Innovation Festival , directly assigned by the Chief Operating Officer of the Kerala Startup Mission , Mr. Tom Thomas.

My task is to discover, design, and fabricate games for the KIF. However, I decided to not just go with the common games. Instead, I took some time to research a few interesting exotic games.

Game Proposal

As per the given task, I proposed 10 different games; 7 games are shortlisted based on the number of players and players engagement, uniqueness, and number of players (single player or multiplayer).

Approval

There is a long procedure to get the funds for any projects in the Kerala Startup Mission. After the final discussions, due to the lack of time, 3 of the games are shortlisted from the 7 games. They are Zig Zag, Gravity Roll, and Hook & Toss .

Game Rules

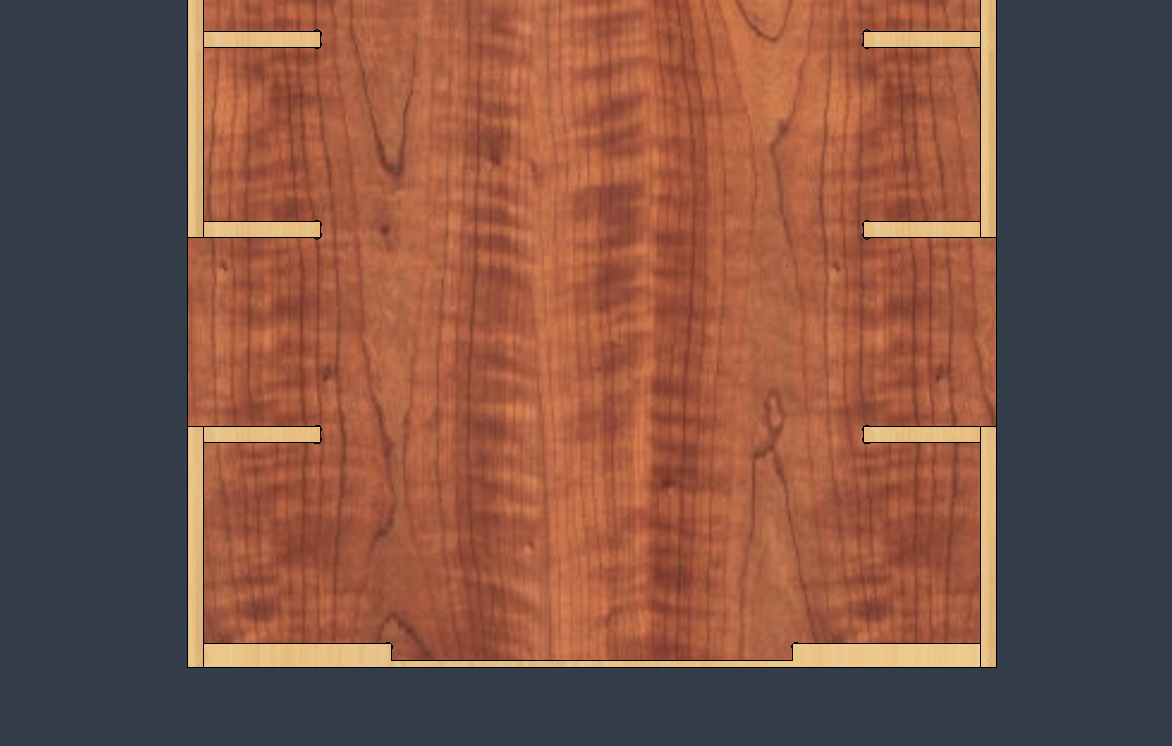

The game consists of a wooden base with a pivot-mounted zig-zag track on top.

To play, the player places a ball at the starting point and uses a control rod to gently tilt the platform. This tilting motion causes the ball to move along the curved zig-zag path. The player must carefully adjust the tilt to guide the ball smoothly through the turns, aiming to reach the highest-scoring zone at the opposite end of the track.

Each player has 5 chances to play, and their points sum will be calculated, and if the player secures a spot within the top 5, they will be marked on the leaderboard, and at the end of the event, the player with the highest score will be the winner.

Project Management

Material Selection

There are different types of materials available for this task, like plywood, OSB, and MDF. However, I decided to choose plywood because of its quality at a reasonable price.

Since the game does not require any complex structure to balance, it is good to go with 12 mm plywood ✅ .

Designing

Usually, I like to draw a rough sketch of the model that I would like to design, using a mechanical pencil and then I try to digitalize to get the form of the project.

Initially, I decided to draw a sketch of the game to obtain the form factor of the game, and after several attempt, I ended up to a final design.

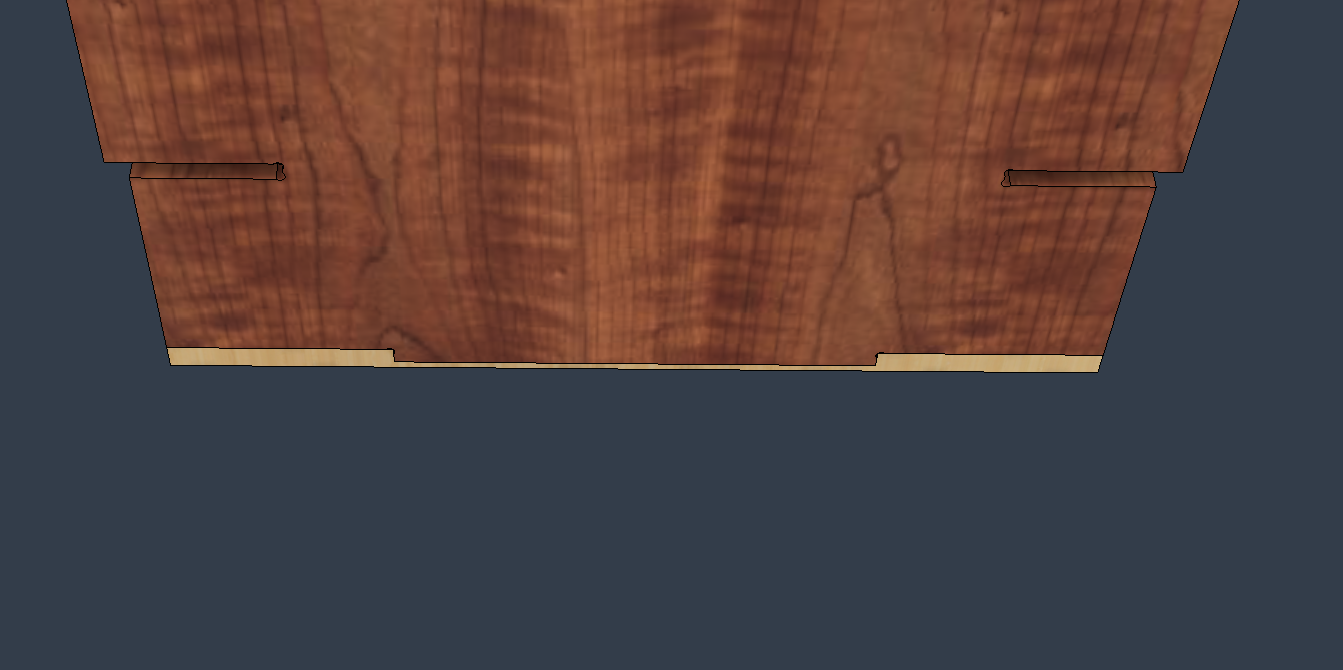

This time I decided to go with the pocket joint and tabs to join the parts.

Design for Manufacturing and Assembly (DFMA)

The design is completely parametric, and the maze is interchangeable. There are few key factors in this design, such as the diameter of the ball, material thickness, the distance of the thread holes from the maze, and the height of the holes. These parameters are the key factors of the design and need to be chosen wisely.

The design is completely done using Fusion 360.

There are few other factors that need to be considered while designing, such as the type of the machine used, the material used, the tool diameter, and so on. Once you are aware of these, then only you can design for manufacturing.

Follow the link below to learn more about computer controlled machining.

fab-academy/week07.html

fab-academy/week07.html

Components to Build

Fabrication

Used the ShopBot CNC machine to cut the 12 mm plywood.

- Initially all the body is converted to components in Fusion 360.

- Arranged the components on a sketch whose dimensions are equal to the dimensions of the 12 mm plywood sheet.

- Added the dog bones to the inner 90-degree corners

- Projected the sketch and exported it in DXF format

- CAM is done using the V Carve software.

Post-Processing

Safety first, always wear:

- Hand gloves

- Safety gloves

- Safety goggles

- Respiratory mask (at least a normal mask)

Finishing Works

Initially, I thought of using wood stain with wood sealer. However, I tried the wood stain on a waste piece, and I found it destroyed the appearance of the wood. So I used just the wood sealer. It took around 1h to dry completely. Varnish is also another option. However, varnish takes around 1-2 days to cure completely, so I found wood sealer works like a charm to get a good finish.

Video

BOM

| S. No | Description | Quantity | Price |

|---|---|---|---|

| 1 | Plywood 12 mm | 1 sheet | ₹ 1800 |

| 2 | Golf Ball | 1 | ₹ 50 |

| 3 | Curtain Steel Rod | 30 cm | ₹ 100 |

| 4 | Rod End POS 8 | 1 | ₹ 230 |

| 5 | 3D Printed Parts | 2h | ₹ 200 |

| 6 | Wood Sealer | 1 | ₹ 250 |

| Total | ₹ 2,630 |

Reference

https://innovationfestival.in/

https://innovationfestival.in/

https://startupmission.kerala.gov.in/

https://startupmission.kerala.gov.in/

https://fabacademy.fablabkerala.in/

https://fabacademy.fablabkerala.in/

https://www.youtube.com/watch?v=HIF2EIAIz30

https://www.youtube.com/watch?v=HIF2EIAIz30