Table of Contents

Project Overview

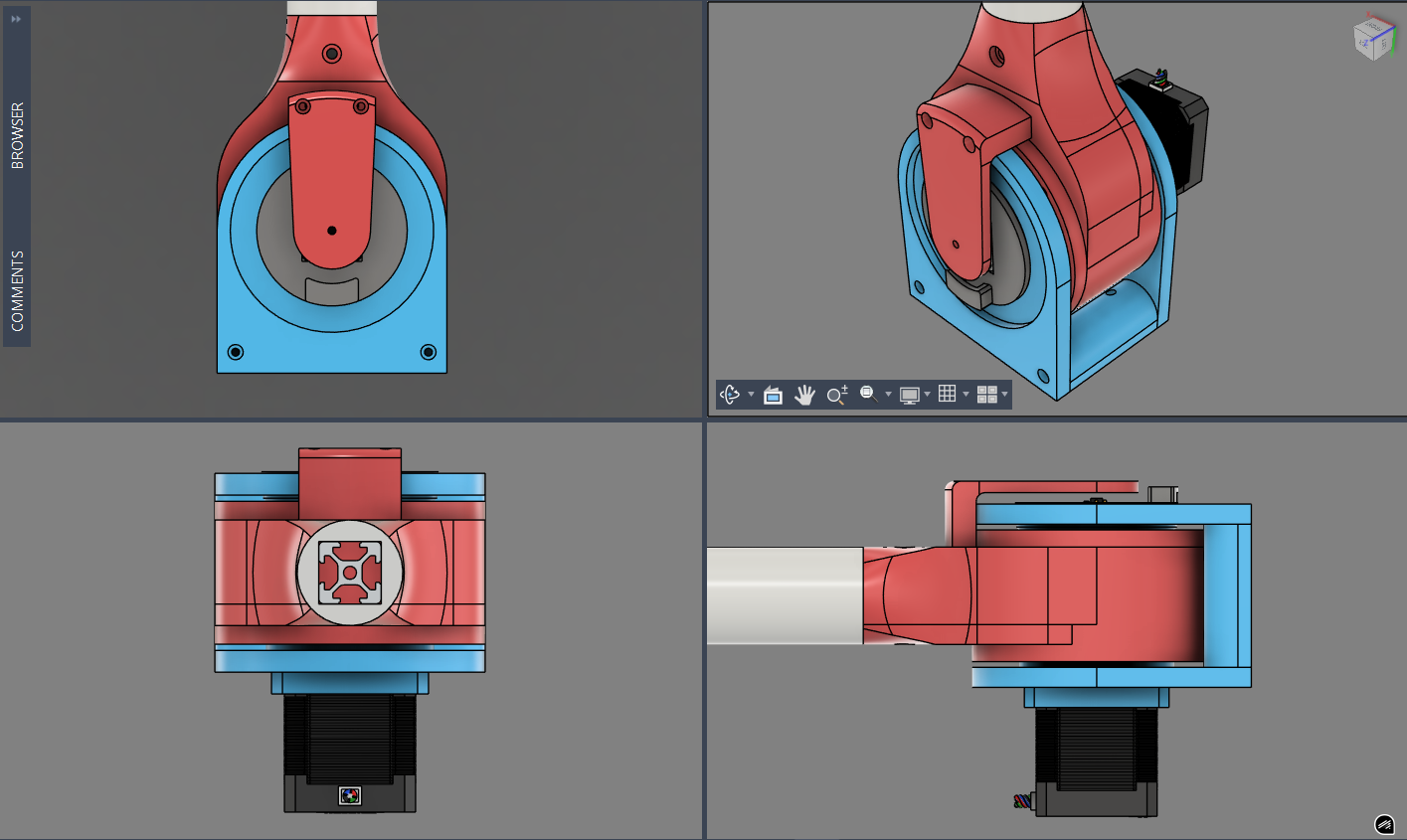

This document details a precision 21:1 cycloidal drive mechanism designed in Fusion 360, built with 3D-printed PETG, actuated by a NEMA17 stepper motor, and controlled by an ESP32 running custom Arduino firmware. Designed for high-torque, low-backlash positioning in robotics and automation applications. The drive achieves a reduction ratio of 21:1, supporting accurate and repeatable motion for high-precision positioning tasks.

Design Goals & Constraints

High reduction ratio (21:1) for strong torque multiplication

3D printability using PETG for rapid prototyping and cost-effectiveness

Minimal mechanical backlash through fit and pin/bearing tolerances

Direct stepper motor drive, controllable by custom firmware

Follow the design for the manufacturing and assembly (DFMA) principle.

Simple assembly using standard bearings, nuts, and bolts

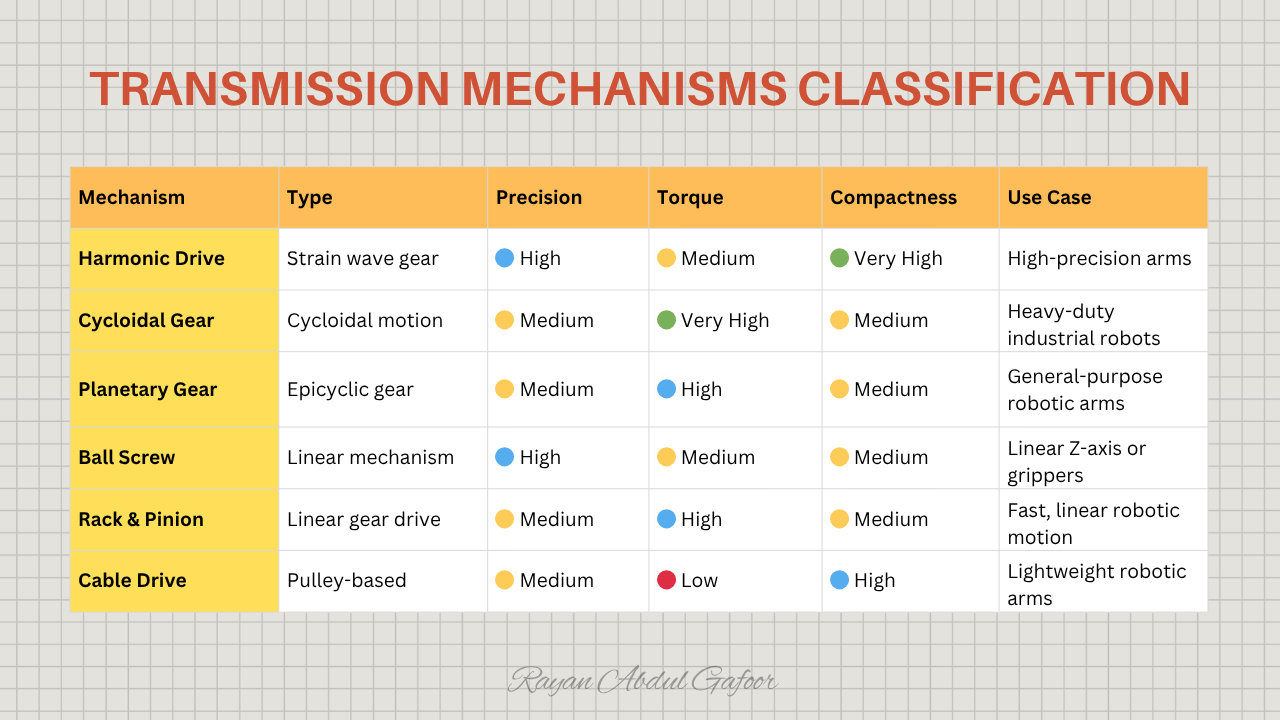

Transmission Mechanisms

Transmission mechanisms are the system that transmits, modifies, or transforms that motion.

Passively transmits energy from actuator to output.

Modifies speed, torque, direction, or type of motion.

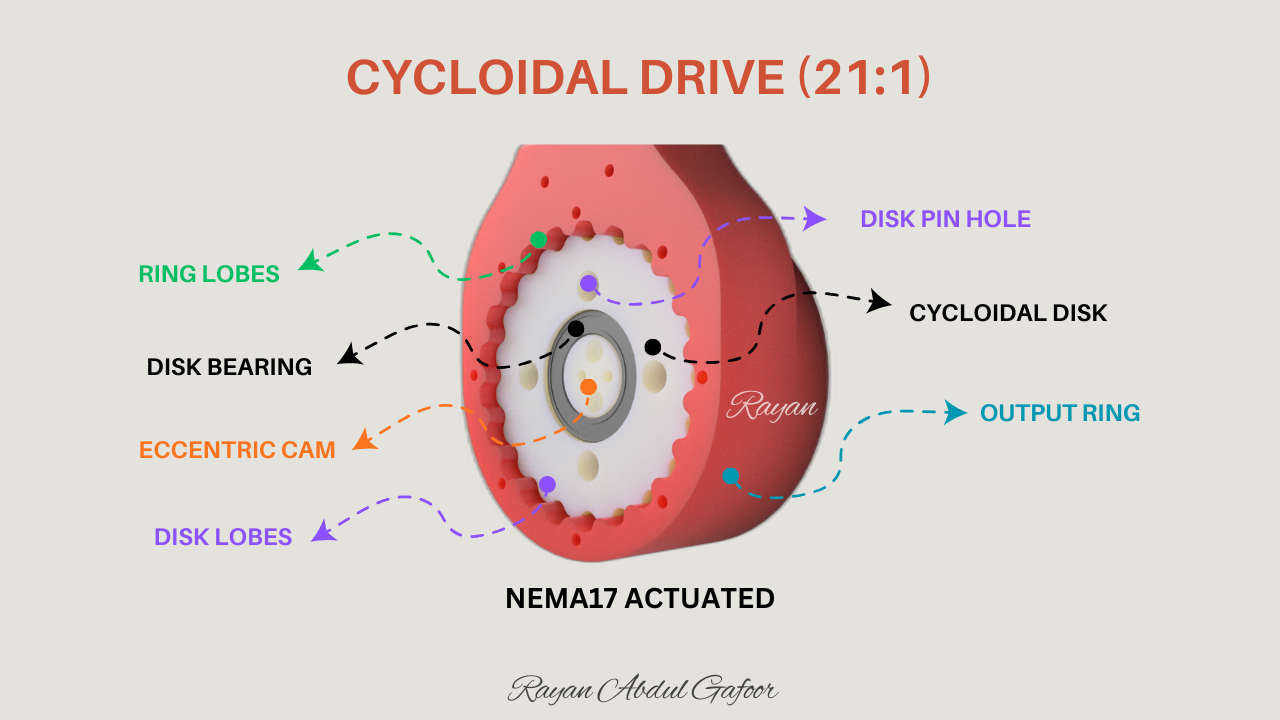

Cycloidal Drive

A cycloidal drive uses an eccentric cam to rotate a lobed cycloidal disc inside a circular array of rollers or pins. As the cycloidal disc rotates, it "walks" around the stationary outer ring, causing differential motion transferred to the output shaft via output pins or followers.

Main Parts:

- Eccentric cam (offsets disc center from input shaft)

- Cycloidal disc (lobed plate with cycloidal profile)

- Ring/pin array (stationary which holds pins or rollers)

- Output shaft (connected to output pins following the disc)

- Return pins/bearings (reduce friction, guide output)

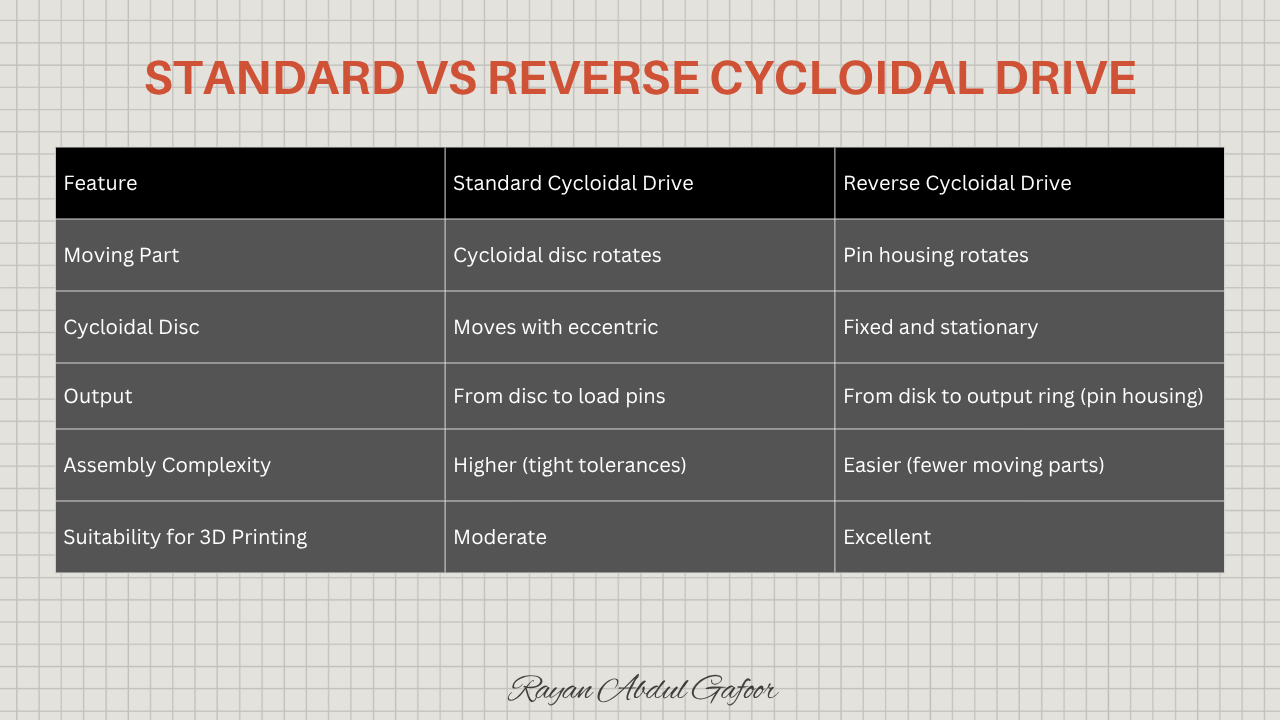

Reverse Cycloidal Drive

A reverse cycloidal drive is a compact, high-torque speed reducer in which the cycloidal disc remains stationary and the output pin housing rotates, producing mechanical advantage through eccentric motion and rolling contact.

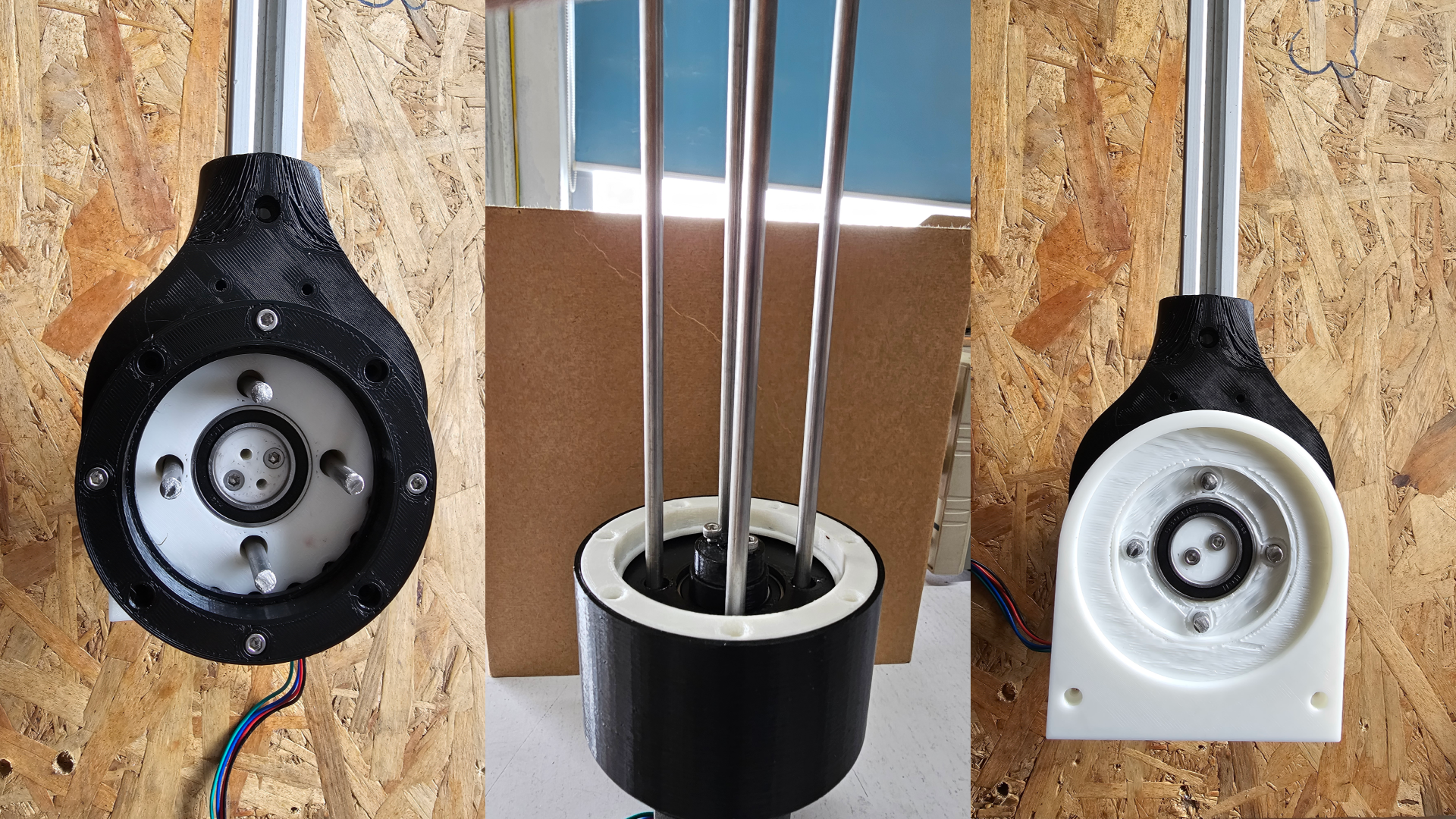

I developed this cycloidal drive for use in my serial robotic manipulator, and I specifically chose the reverse cycloidal drive because it keeps the drives output perfectly coaxial with the robot’s joint axis. This eliminates any physical offset between the drive and the link, ensuring that the joint geometry remains clean and centered.

A standard (normal) cycloidal drive typically introduces an offset between the gearbox center and the link center, which adds an extra rigid translation to the robot’s kinematic chain. Such an offset must then be explicitly included in all mathematical models forward kinematics, inverse kinematics, jacobian calculations, and dynamic equations, to maintain accuracy.

By using a reverse cycloidal drive, I avoid these unnecessary geometric complications, maintain a coaxial joint layout, and ensure simpler, more robust kinematic modelling for the manipulator.

Working Principle

A motor drives an eccentric shaft that orbits inside a stationary cycloidal disc.

Instead of the cycloidal disc rotating, the pin housing (or output ring) follows the orbital path.

As the eccentric rotates, each lobe of the disc sequentially engages the surrounding pins, causing the output ring to rotate smoothly.

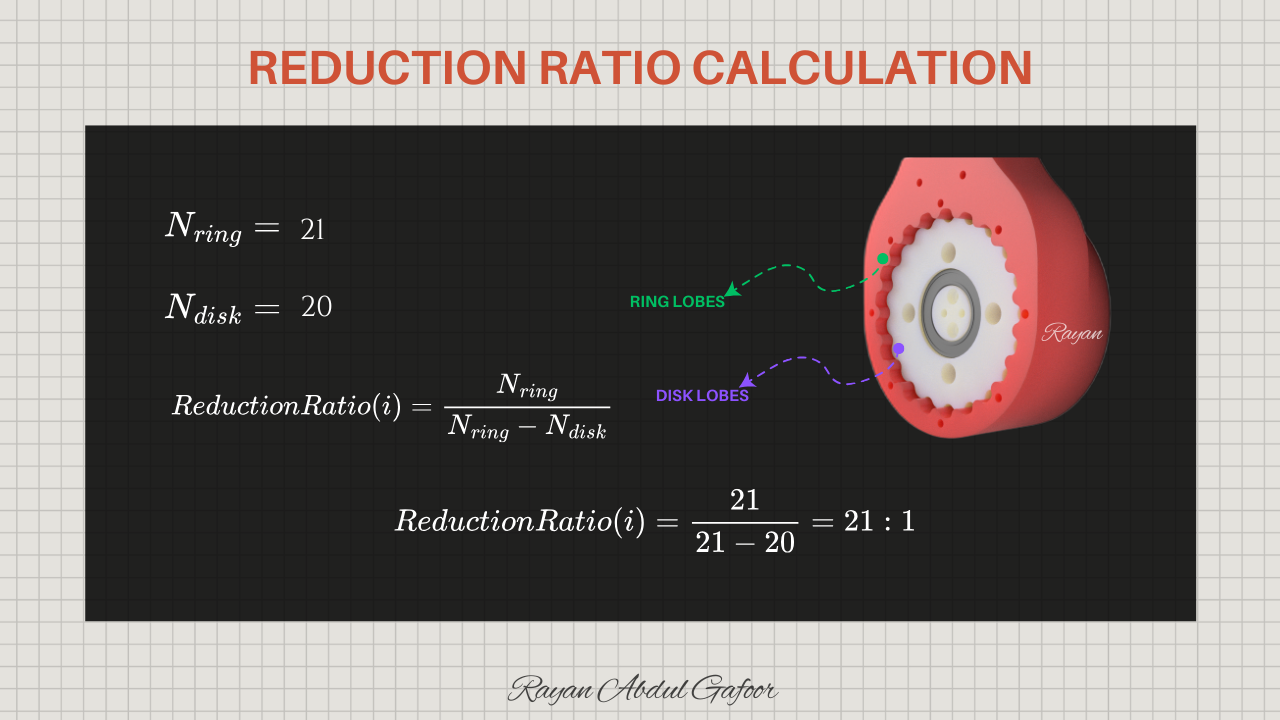

The reduction ratio is generated by the difference between the number of pins and cycloidal lobes, following the same mathematical relationship as a normal cycloidal drive.

The motion is transmitted through rolling contact, giving the drive high efficiency and smooth torque output.

Advantages of the Reverse Cycloidal

More stable load path and easier assembly

Output remains coaxial with the motor shaft

Easier integration into serial manipulator joints

Lower backlash due to fixed geometry and rigid center plate.

Compact and easy to integrate into robotic joints using NEMA17 motors.

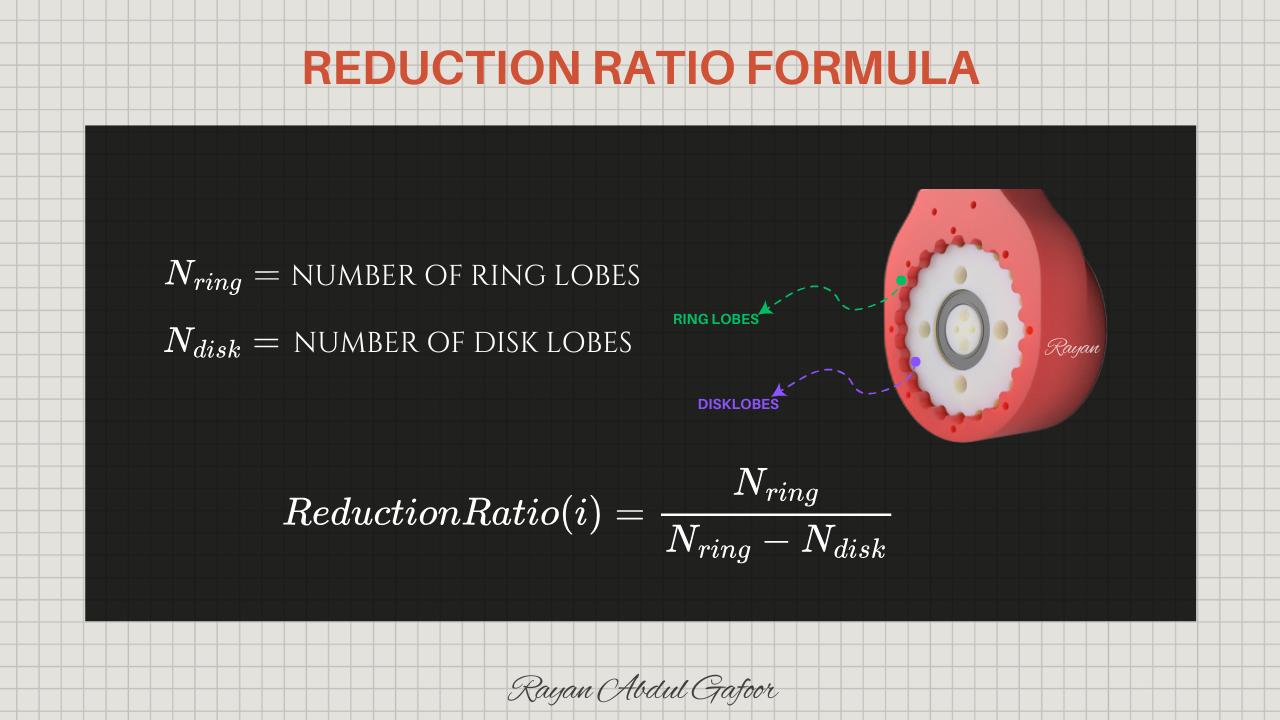

Reduction Ratio

Kinematic Behavior

The eccentric shaft causes a perfect cycloidal motion path around the fixed disc.

Each rotation of the eccentric advances the output ring by 1 pin step.

After one full motor rotation, the output rotates only 1/21 of a turn (for 21:1), creating the reduction.

Load is distributed across many lobes simultaneously, improving torque and reducing wear.

The motion of the reverse cycloidal drive is smoother at low speeds because the fixed disc acts as a rigid guide.

Dynamic Characteristics

Rolling contact between the lobes and pins produces high torque-density.

The fixed cycloid plate absorbs eccentric forces, reducing bearing vibration.

Radial forces from the eccentric motion are transferred mainly to the output ring bearings.

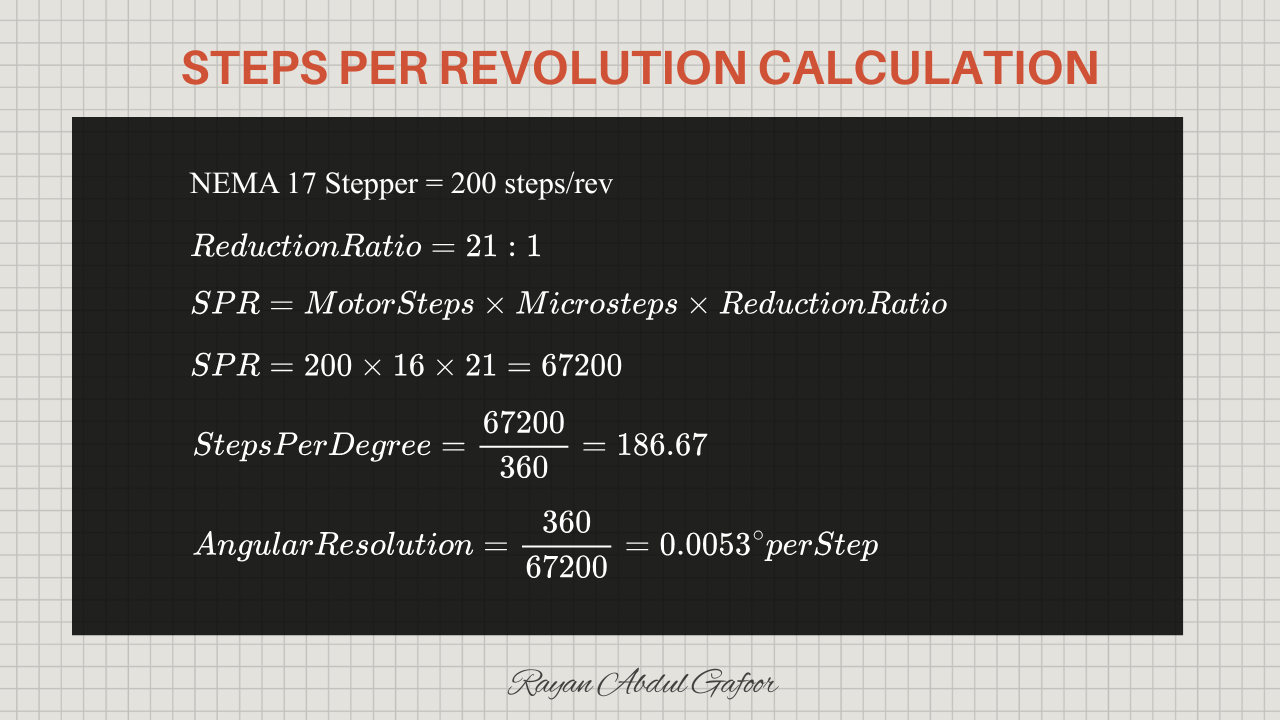

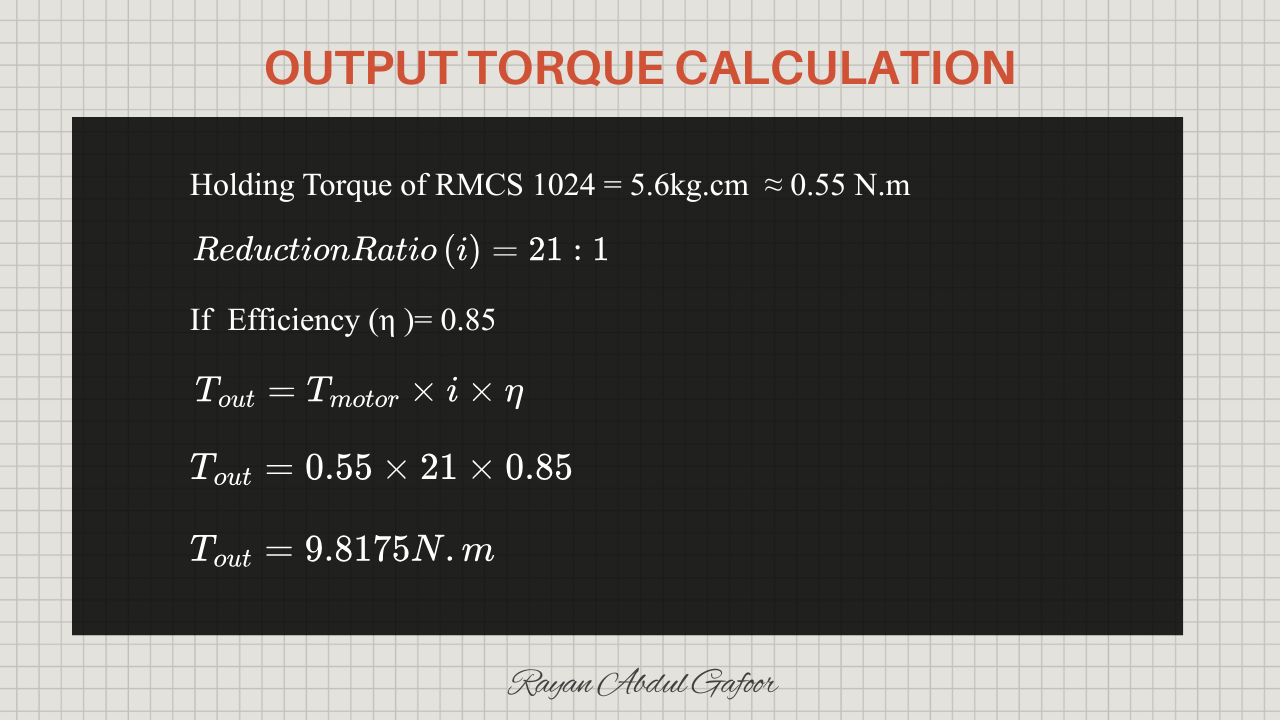

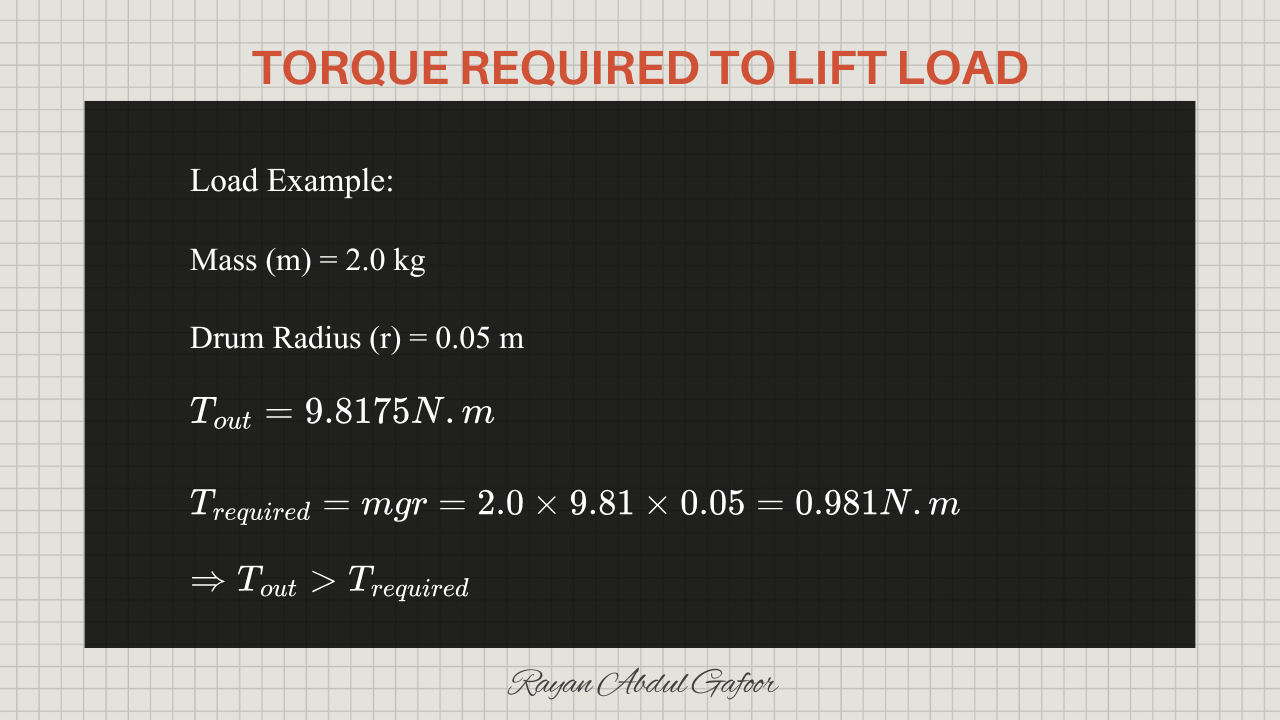

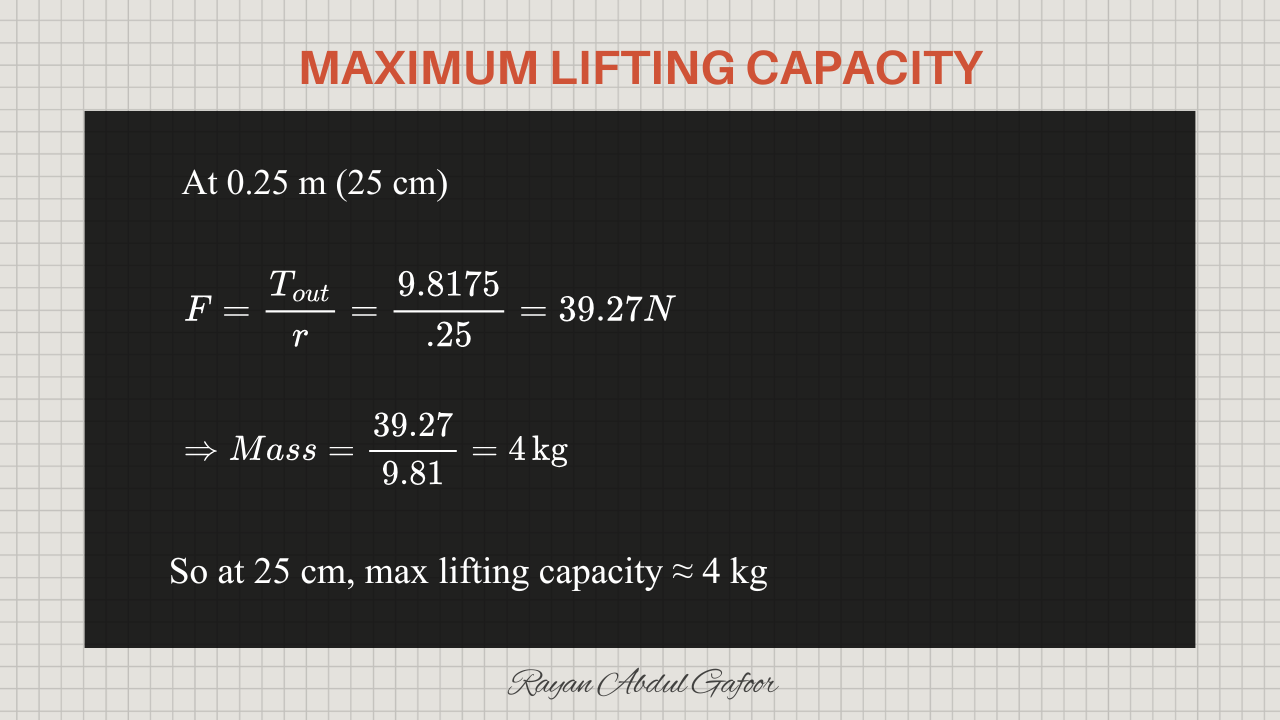

Calculations

Designing

The design process of this cycloidal drive involves carefully selecting and refining several geometric and mechanical parameters such as the number of rollers, number of cycloidal lobes, pitch-circle diameter, roller diameter, eccentricity, base circle diameter, hole dimensions on the cycloidal disk, clearances for smooth motion, thickness of the cycloidal plate, and the output pin layout.

Each of these factors influences the motion profile, load distribution, efficiency, and overall behavior of the drive, and their relationships require multiple interconnected calculations to determine the correct proportions, spacing, and geometry.

Through iterative adjustments guided by these calculations, the design is tuned to achieve the desired reduction ratio, torque capacity, smooth operation, and compact form.

The final geometry is optimized for strength, reliability, and manufacturability, ensuring that the PETG-printed drive performs effectively as a robotic joint actuator.

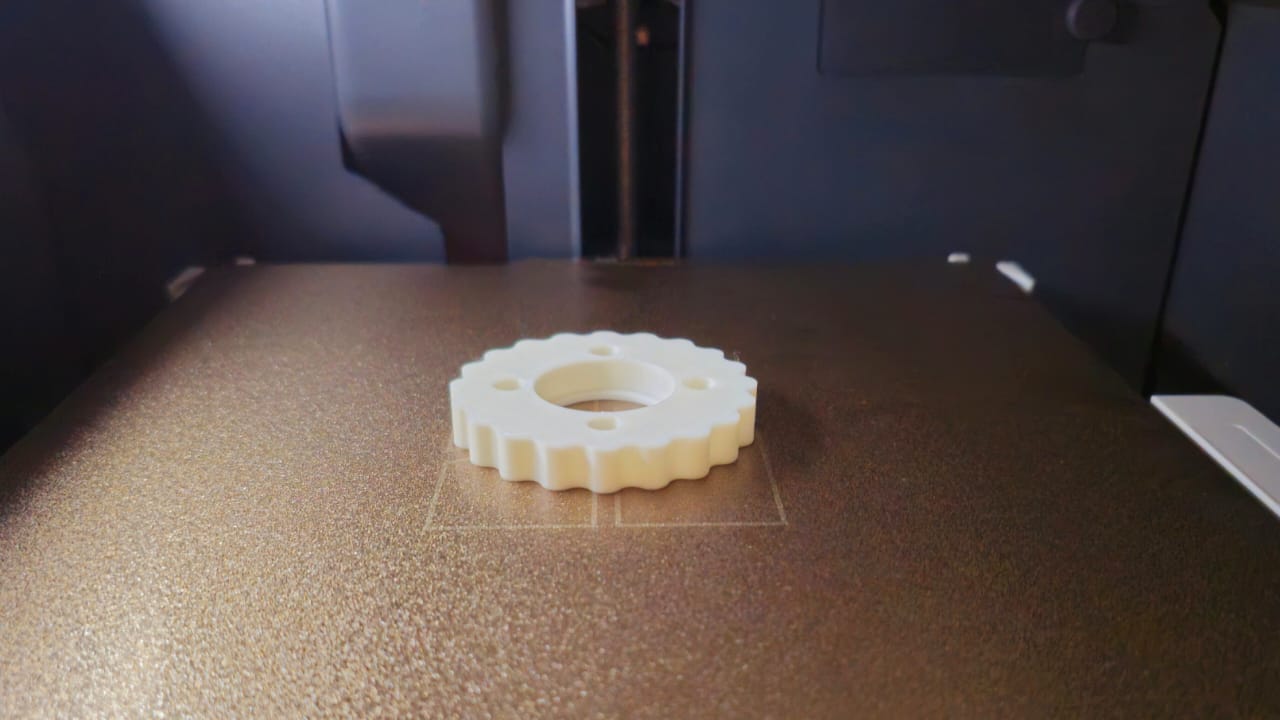

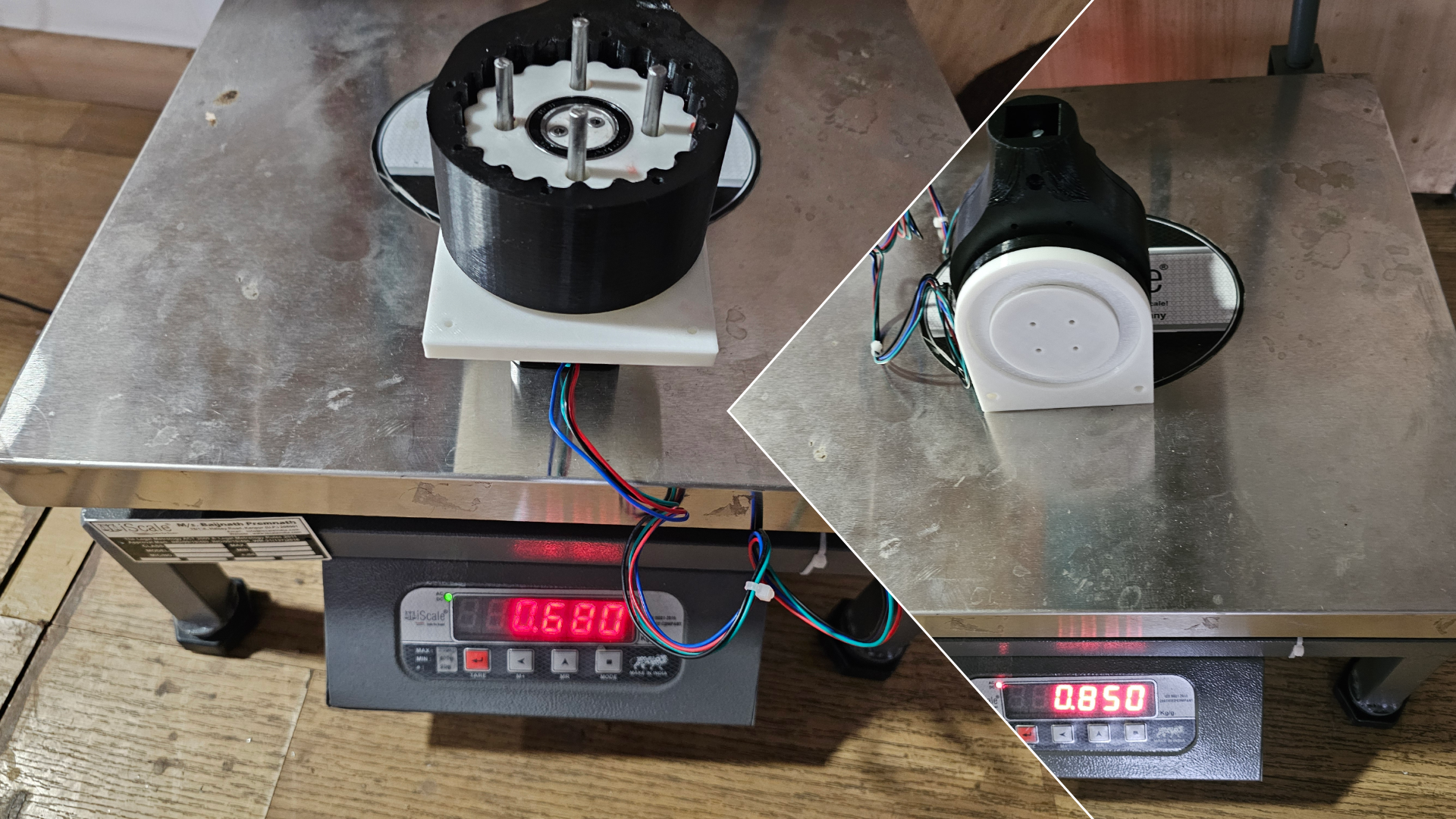

Digital Fabrication

All components were 3D printed on a Bambu Lab P1S using black and white PETG. The print configuration included 5 wall loops for increased strength and rigidity, and a 50% infill density to ensure optimal structural integrity under load.

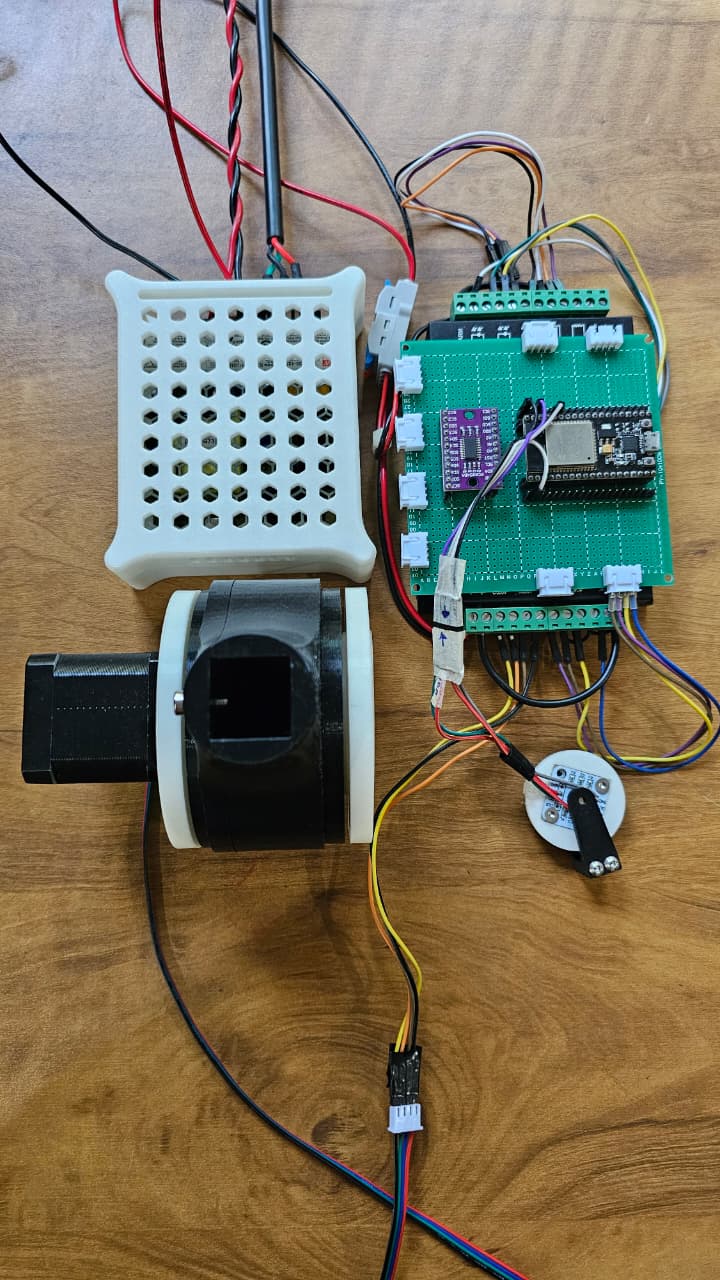

Hardware Overview

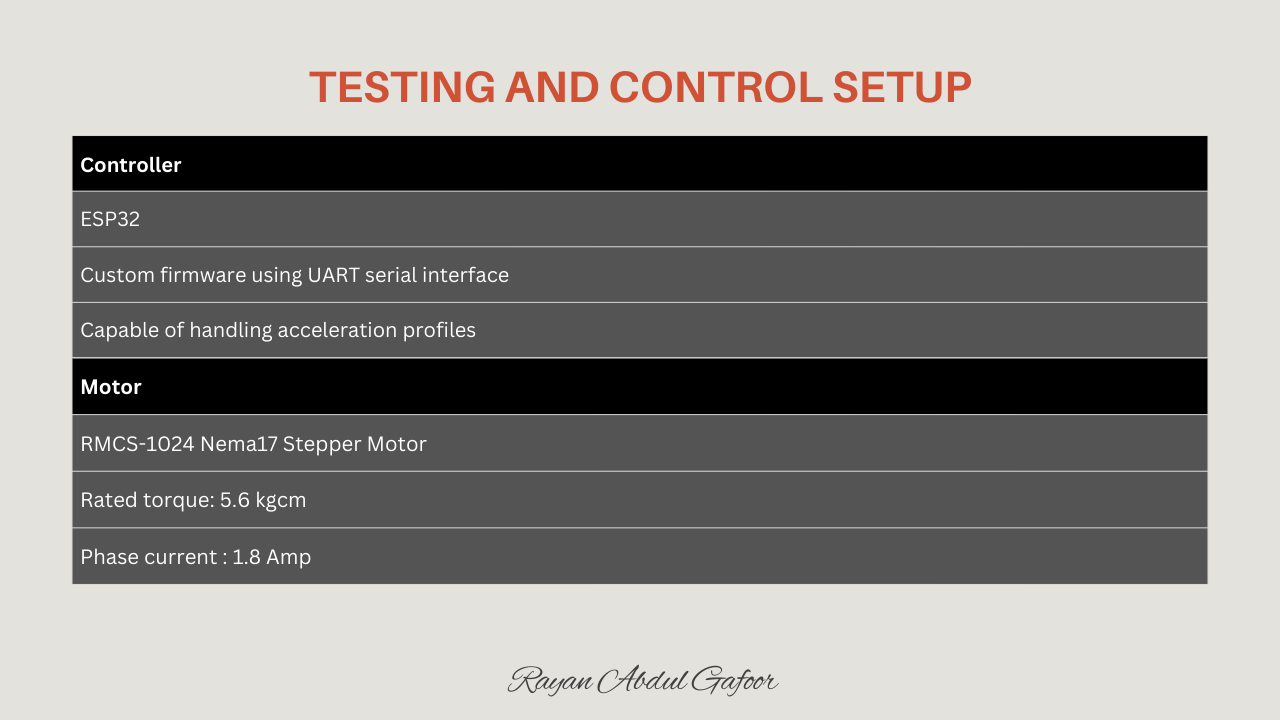

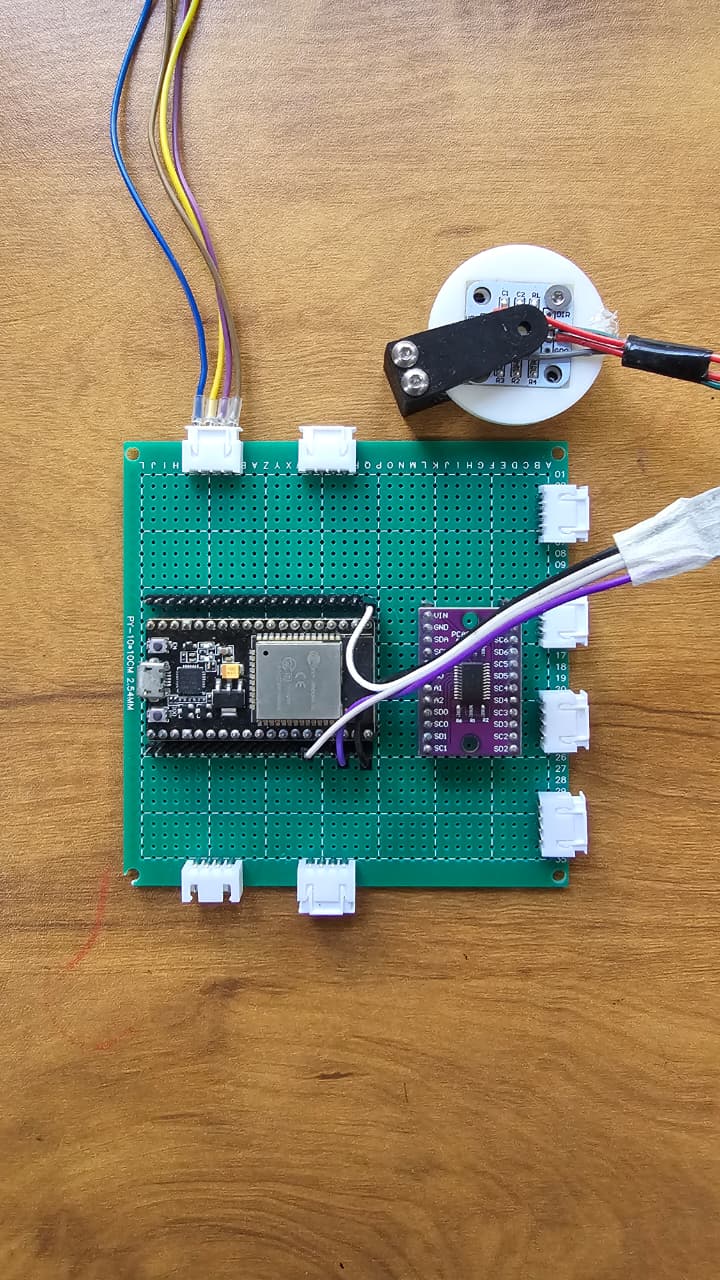

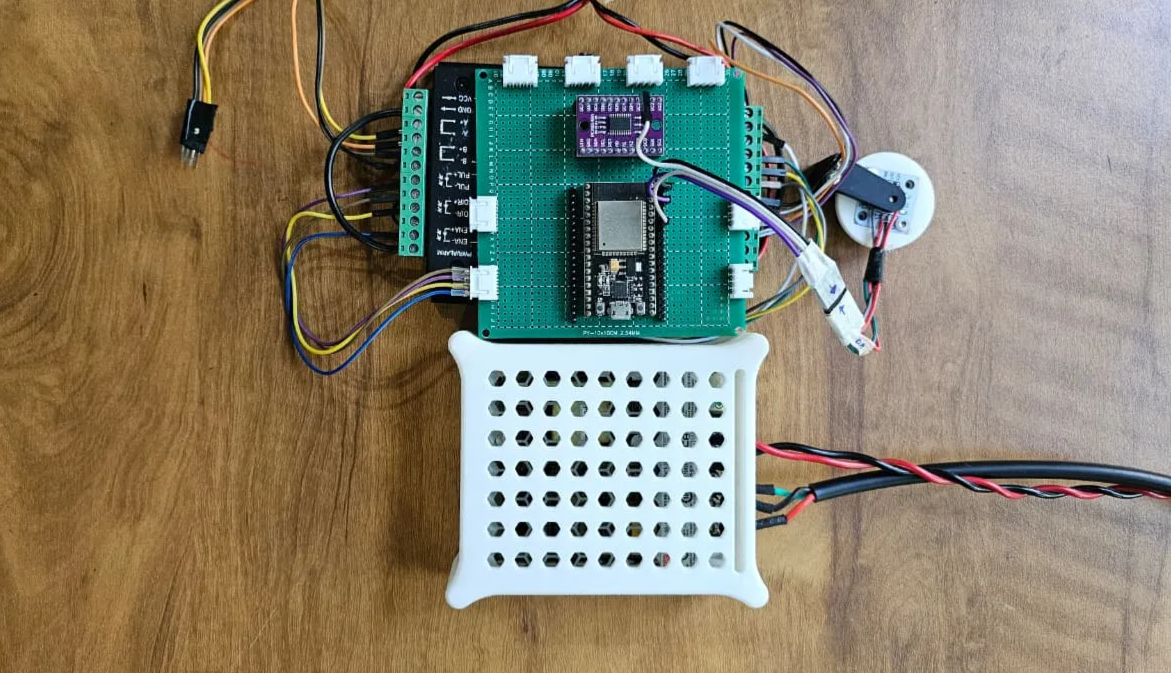

Controller

- ESP32

- Custom firmware using UART serial interface

- Capable of handling acceleration profiles and fast control loops

Motor

- RMCS-1024 Nema17 Stepper Motor

- Rated torque: 5.6 kgcm

- Phase current : 1.8 Amp

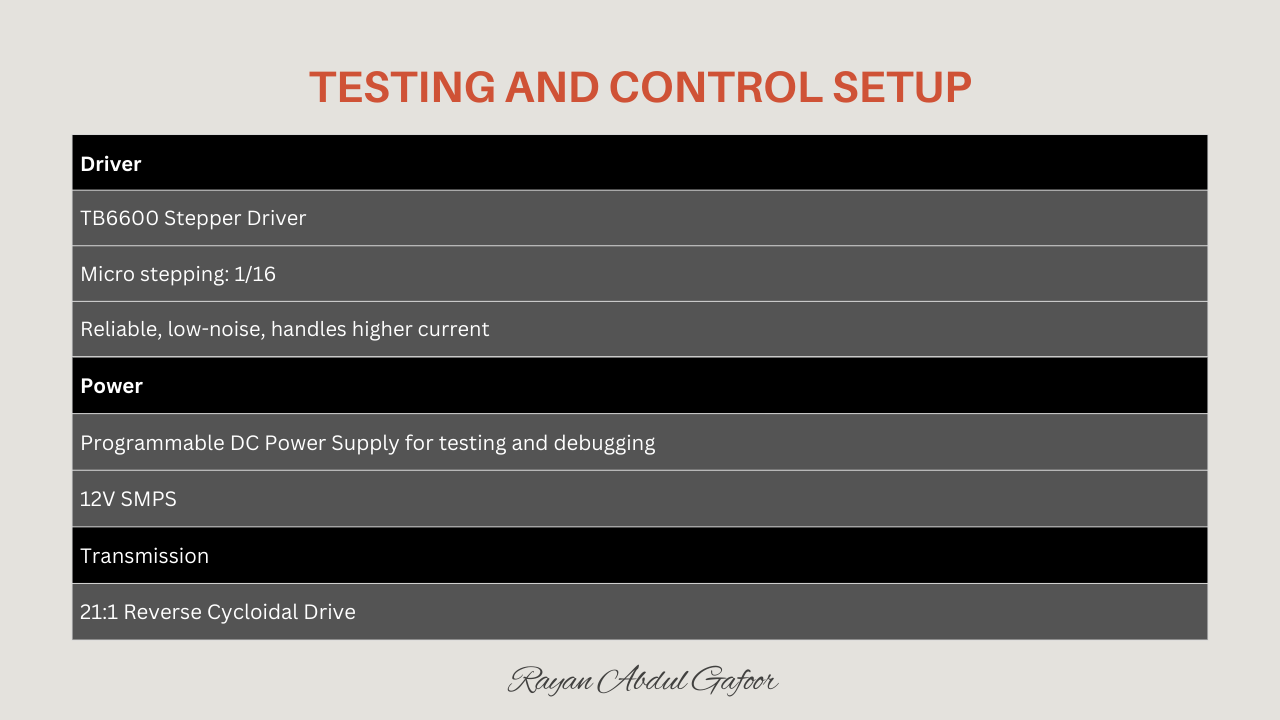

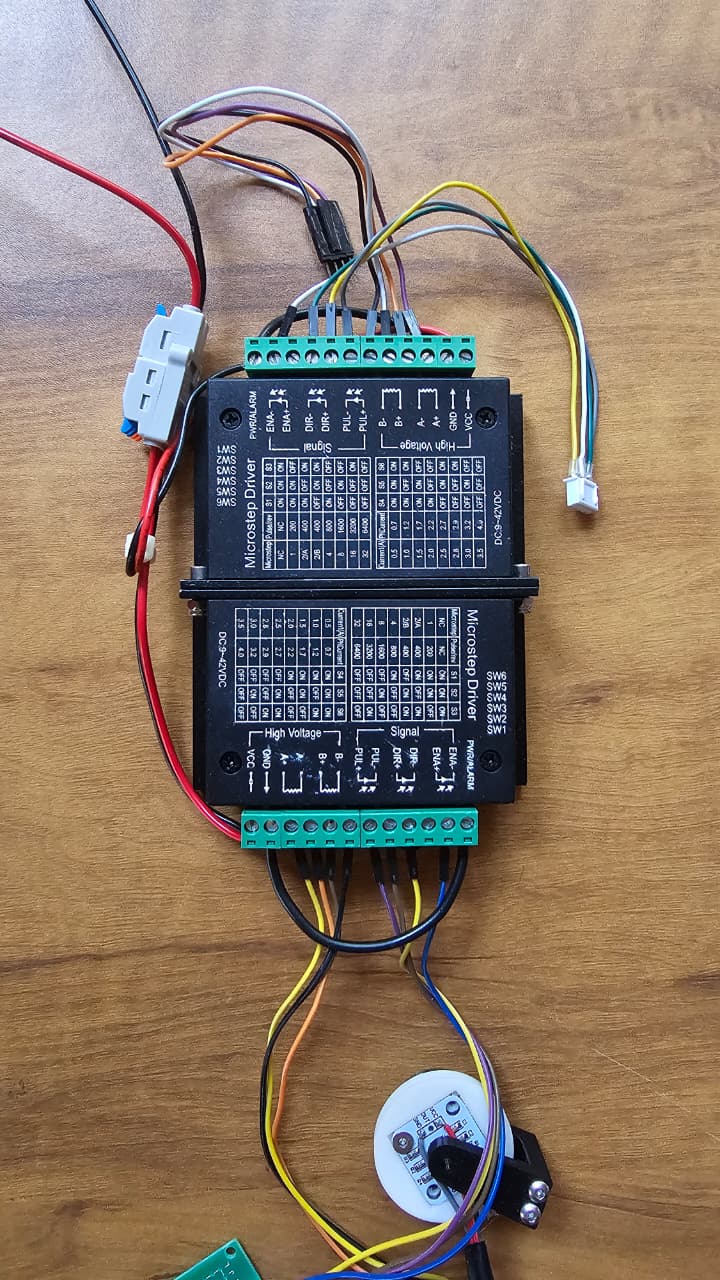

Driver

- TB6600 Stepper Driver

- Micro stepping: 1/16

- Reliable, low-noise, handles higher current

Power

- Programmable DC Power Supply for testing and debugging then used SMPS

Transmission

- 21:1 Reverse Cycloidal Drive

- 3D printed in PETG using Bambu Lab P1S

- Lightweight + durable

- Naturally back-drivable, allowing safer human-robot interaction

Assembly

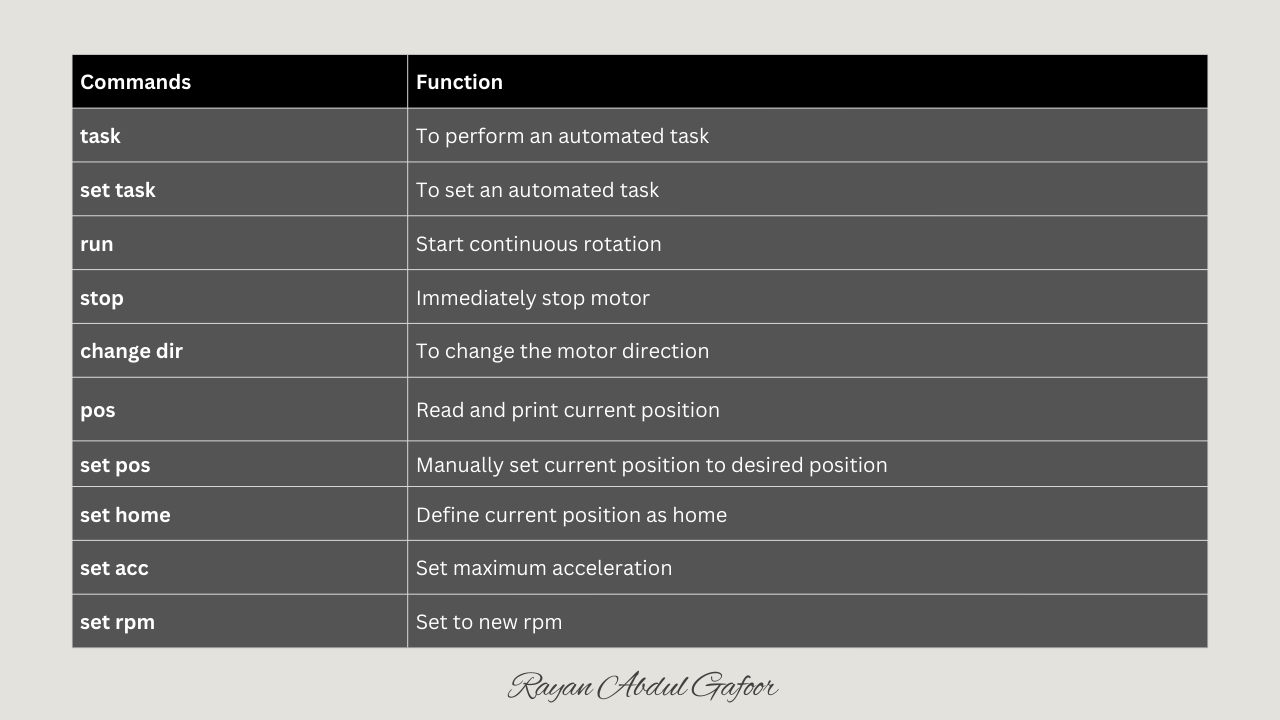

Custom Firmware

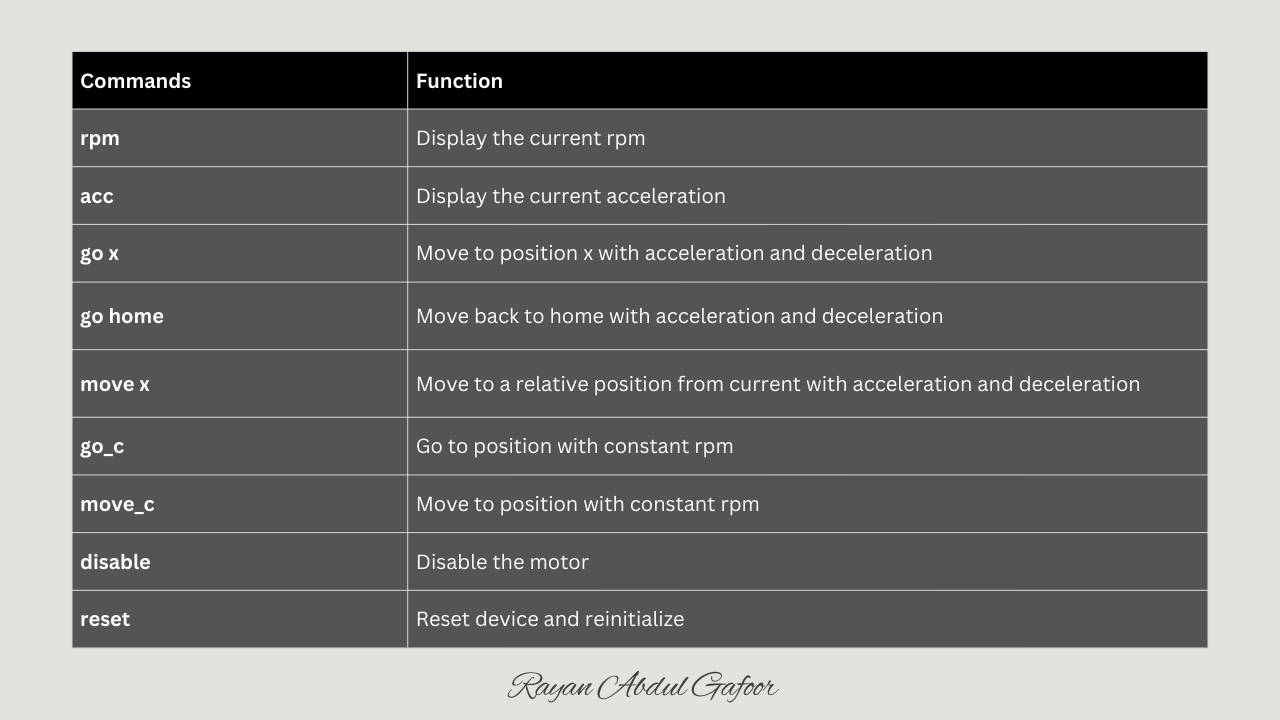

I wrote a custom serial-command firmware that allows complete control of the cycloidal actuator.

Testing the Drive

Cycloidal Drives in Robots

Cycloidal drives are widely used in robotic joints because they offer high torque in a compact and lightweight design.

Their low backlash enables precise and repeatable motion, which is essential for accurate robotic positioning.

The high shock-load resistance of cycloidal drives protects robot joints from sudden impacts during movement or collisions.

Their smooth low-speed performance makes them ideal for tasks requiring slow, controlled, and stable robotic motion.

They allow robots to carry heavier payloads without increasing the size or weight of the actuator.

The high reduction ratios achievable with cycloidal drives enable small motors like NEMA17 or NEMA23 to deliver large output torques.

Robots benefit from the reduced vibration of cycloidal drives, resulting in smoother trajectories and improved control accuracy.

Cycloidal drives maintain performance even under repeated directional changes, making them ideal for dynamic robotic applications.

Advantages of Cycloidal Drive

Back-drivable, Smooth and quiet at medium speeds, High torque-to-size ratio, easy integration into multi-DOF kinematics.

They offer high torque density because multiple lobes share the load simultaneously.

They can withstand extremely high shock loads, often up to five times the rated torque.

Cycloidal drives have naturally low backlash due to their geometry and load distribution.

They deliver smooth and precise motion even at very low speeds.

Their rolling motion helps absorb vibration and reduce resonance.

Cycloidal mechanisms are reliable and durable because their load is distributed over many contact points.

Limitations of Cycloidal Drive

Cycloidal drives are harder to manufacture because they require precise geometry and tight tolerances.

Their design involves complex kinematic and geometric calculations that are harder than spur or planetary systems.

The eccentric motion creates high radial loads on bearings, requiring strong and well-aligned bearing support.

They are difficult to back-drive due to high reduction ratios and friction.

They require lubrication to prevent wear and ensure smooth operation.